BAGGING A NEW LIVER

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

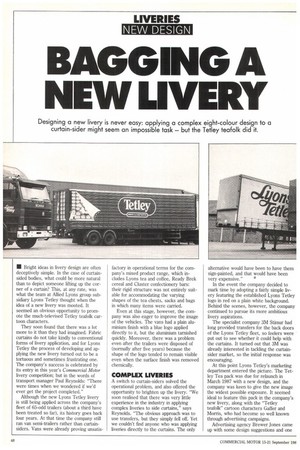

Designing a new livery is never easy: applying a complex eight-colour design to a curtain-sider might seem an impossible task — but the Tetley teafolk did it.

• Bright ideas in livery design are often deceptively simple. In the case of curtainsided bodies, what could be more natural than to depict someone lifting up the corner of a curtain? This, at any rate, was what the team at Allied Lyons group subsidiary Lyons Tetley thought when the idea of a new livery was mooted. It seemed an obvious opportunity to promote the much-televised Tetley teafolk cartoon characters.

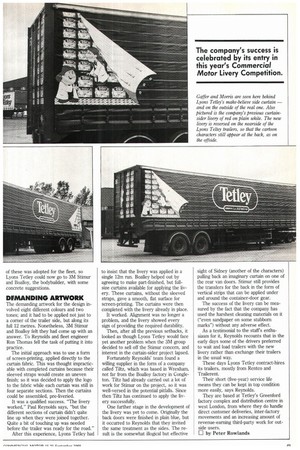

They soon found that there was a lot more to it than they had imagined. Fabric curtains do not take kindly to conventional forms of livery application, and for Lyons Tetley the process of developing and applying the new livery turned out to be a tortuous and sometimes frustrating one. The company's success is celebrated by its entry in this year's Commercial Motor livery competition; but in the words of transport manager Paul Reynolds: "There were times when we wondered if we'd ever get the project completed."

Although the new Lyons Tetley livery is still being applied across the company's fleet of 65-odd trailers (about a third have been treated so far), its history goes back four years. At that time the company still ran van semi-trailers rather than curtainsiders. Vans were already proving unsatis factory in operational terms for the company's mixed product range, which includes Lyons tea and coffee, Ready Brek cereal and Cluster confectionery bars: their rigid structure was not entirely suitable for accommodating the varying shapes of the tea chests, sacks and bags in which many items were carried.

Even at this stage, however, the company was also eager to improve the image of the vehicles. The vans had a plain aluminium finish with a blue logo applied directly to it, but the aluminium tarnished quickly. Moreover, there was a problem even after the trailers were disposed of (normally after five years) because the shape of the logo tended to remain visible even when the surface finish was removed chemically.

COMPLEX LIVERIES

A switch to curtain-siders solved the operational problem, and also offered the opportunity to brighten up the livery. "We soon realised that there was very little experience in the industry in applying complex liveries to side curtains," says Reynolds. "The obvious approach was to use transfers, but they simply fell off. Yet we couldn't find anyone who was applying liveries directly to the curtains. The only alternative would have been to have them sign-painted, and that would have been very expensive." • In the event the company decided to mark time by adopting a fairly simple livery featuring the established Lyons Tetley logo in red on a plain white background. Behind the scenes, however, the company continued to pursue its more ambitious livery aspirations.

The specialist company 3M Stimur had long provided transfers for the back doors of the Lyons Tetley fleet, so feelers were put out to see whether it could help with the curtains. It turned out that 3M was already interested in tackling the curtainsider market, so the initial response was encouraging.

At this point Lyons Tetley's marketing department entered the picture. The Tetley Tea pack was due for relaunch in March 1987 with a new design, and the company was keen to give the new image the widest possible exposure. It seemed ideal to feature this pack in the company's new livery, along with the "Tetley teafolk" cartoon characters Gaffer and Morris, who had become so well known through advertising campaigns.

Advertising agency Brewer Jones came up with some design suggestions and one of these was adopted for the fleet, so Lyons Tetley could now go to 3M Stimur and Boalloy, the bodybuilder, with some concrete suggestions.

DEMANDING ARTWORK

The demanding artwork for the design involved eight different colours and two tones; and it had to be applied not just to a corner of the trailer side, but along its full 12 metres. Nonetheless, 3M Stimur and Boalloy felt they had come up with an answer. To Reynolds and fleet engineer Ron Thomas fell the task of putting it into practice.

The initial approach was to use a form of screen-printing, applied directly to the curtain fabric. This was thought impracticable with completed curtains because their sleeved straps would create an uneven finish; so it was decided to apply the logo to the fabric while each curtain was still in four separate sections. Then the curtains could be assembled, pre-liveried.

It was a qualified success. "The livery worked," Paul Reynolds says, "but the different sections of curtain didn't quite line up when they were joined together. Quite a bit of touching up was needed before the trailer was ready for the road."

After this experience, Lyons Tetley had to insist that the livery was applied in a single 12m run. Boalley helped out by agreeing to make part-finished, but fullsize curtains available for applying the livery. These curtains, without the sleeved straps, gave a smooth, flat surface for screen-printing. The curtains were then completed with the livery already in place.

It worked. Alignment was no longer a problem, and the livery showed every sign of providing the required durability.

Then, after all the previous setbacks, it looked as though Lyons Tetley would face yet another problem when the 3M group decided to sell off the Stirnur concern, and interest in the curtain-sider project lapsed.

Fortunately Reynolds' team found a willing supplier in the form of a company called Tiltz, which was based in Wrexham, not far from the Boalloy factory in Congleton. Tiltz had already carried out a lot of work for Stimur on the project, so it was well-versed in the potential pitfalls. Since then Tiltz has continued to apply the livery successfully.

One further stage in the development of the livery was yet to come. Originally the back doors were finished in plain blue, but it occurred to Reynolds that they invited the same treatment as the sides. The result is the somewhat illogical but effective sight of Sidney (another of the characters) pulling back an imaginary curtain on one of the rear van doors. Stimur still provides the transfers for the back in the form of vertical strips that can be applied under and around the container-door gear.

The success of the livery can be measured by the fact that the company has used the harshest cleaning materials on it ("even sandpaper on some stubborn marks") without any adverse effect.

As a testimonial to the staff's enthusiasm for it, Reynolds recounts that in the early days some of the drivers preferred to wait and load trailers with the new livery rather than exchange their trailers in the usual way.

These days Lyons Tetley contract-hires its trailers, mostly from Renteo and Trailerent.

Their short (five-year) service life means they can be kept in top condition more easily, says Reynolds.

They are based at Tetley's Greenford factory complex and distribution centre in west London, from where they do handle direct customer deliveries, inter-factory movements and an increasing amount of revenue-earning third-party work for outside users.

0 by Peter Rowlands