WEATHERING THE STORM

Page 96

Page 97

If you've noticed an error in this article please click here to report it so we can fix it.

• The main builders of refrigerated vans in Scotland are to be weathering the economic storm and market-leader Gray & Adams is looking to the future with a new factory in Doncaster and plans for tackling the European market.

Geography has never been a problem for Gray & Adams, based on Scotland's north-east coast at Fraserburgh. The company's customers are spread throughout the United Kingdom and Ireland, and Peter Gray points to the network of depots providing a full service back-up; "Fraserburgh is our head office and main works, and we have our Dunfermline depot in the central belt of Scotland and the Northern Ireland centre at Newtonabbey. In addition, we have our Nottingham agents, Atlas Refrigerated Vehicles," he says.

"This month we have opened our new sales, service and repair depot at Doncaster, which will allow us to provide a wider service south of the border."

Fraserburgh is the main factory for refrigerated trailers, although some rigids are bodied there and accident repair work is handled; the factory also produces kits which are sent for assembly at Dunfermline, Ireland, Nottingham and now Doncaster.

-We are very much specialists in insulated and temperature-controlled bodies," says Gray. "We are suppliers to all the major supermarket chains, and we build for most of the hauliers handling general refrigerated work."

With a growing list of blue-chip customers, Gray & Adams has gone for BS5750 certification. "We are in the final stages of assessment and hoping for certification in the next few months," says Gray. "It has been a lot of work, but we found it refreshing and worthwhile. We have learned from our BS5750 experience at Fraserburgh and the benefits will be passed on to our other depots."

Gray & Adams has seen some very impressive growth during its more than 30 years in business. It is still wholly family-owned, led by Jim Gray and Jim Adams, with directors Lewis Gray, Peter Gray and James Gray Jr.

Over the past few years the company has invested heavily in purpose-built building, plant, machinery and computeraided design, draughting and costing systems.

The new Doncaster depot site has been totally refurbished, and will provide customers in the north and east of England with a convenient service centre. The site is also important to G&A's ambitions, as Doncaster is a Channel Tunnel railhead, and Peter Gray sees Europe as an increasingly important market for the company. "We build specialist quantities for overseas customers, but after 1992 we shall be looking for expansion, possibly in conjunction with companies over there," he says.

Gray reckons that G&A's position as a specialist reefer builder has helped the company survive the UK's economic downturn. "We are having to fight hard for the business we get," he says, "but we are holding on to our customers because we are dedicated to the food industry."

SPECIALISED BODIES

With growing concern about food freshness, the reefer market is demanding increasingly specialised bodies. Gray reports a growing demand for G&A's multi-compartment controlled temperature reefer, which is fitted with two interior moving bulkheads giving a variable compartment load space. This provides temperatures ranging from 30°C to +26°C, allowing deep-frozen, controlled-chilled and controlled ambient goods to be carried in the same body.

Two other specialised products coming to the fore are rolling-deck trailers, and full refrigerated double-deck trailers.

"The rolling-deck trailers double the capacity of a 24 or 26-pallet trailer. using a unique rolling bogie system which is stored in the roofline when not in use," says Peter Gary. "It is ideal for goods that cannot be stacked more than 1,200mm high. The doubledeck trailers are suitable for carrying roll cages, which gives a 60% increase in capacity over a standard trailer."

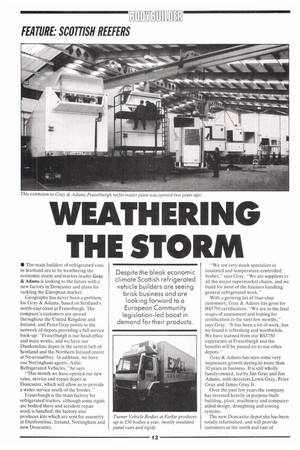

South from Fraserburgh, at Forfar, Turner Vehicle Bodies produces up to 150 bodies a year, mostly insulated and refrigerated. Trailers represent a small proportion of Turner's business, with a greater concentration on insulated panel vans and bodies on rigids.

Managing director Andrew Turner

says that the business is growing gradually, with customers throughout Scotland and in many parts of England. "Our customers look for a better quality product," he says. -These days they are tending to look further afield when they are making their choice."

Turner feels that post-1992 Europe, while important to buyers' attitudes, will not be an important selling ground for his company, but he recognises that EC legislation will increase demand for temperature-controlled food distribution vehicles.

-Our bodies are designed for the rigours of Scotland's roads," he says. "Outside the central belt and a few main routes to the north, the quality and size of roads is variable, and this, along with the important consideration of ferry charges, dictates the size and quality of body required by our customers.

"One of our strengths is adaptability. We build insulated and refrigerated bodies on a wide range of chassis, to a wide range of sizes, to suit our customers' requirements," says Turner.

With Gray & Adams building for the refrigerated trailer market and Turner concentrating on panel vans and bodies on rigids. Scottish builders can offer a complete range of products. But there are other firms who will produce refrigerated bodies to order, like Penman Engineering at Dumfries.

With an established reputation as builders of specialist vehicles, Penman reckons that refrigerated bodies on rigids represent 10% of its output. Although Penman does not build trailers, it does build insulated and refrigerated curtainsiders on trailers.

REPAIR WORK

Two of the major English refrigerated bodybuilders have Scottish service depots that repair and modify bodies for local customers. York Transport Engineering's Glasgow depot handles all levels of repair work, and will tackle modifications such as trailer multi-compartment conversions.

Crane Fruehauf has built refrigerated bodies on rigids at its depot at Whitburn, in West Lothian, and will quote for work of this type as well as for less specialised bodies.

Scottish bodybuilders are notoriously reticent. When pressed, they will admit that business is good, and is holding up in spite of the economic downturn, but they say that some "silly prices" are being quoted by competitors desperate for work. O by Gavin Booth