PRECIOUS

Page 52

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

Alin

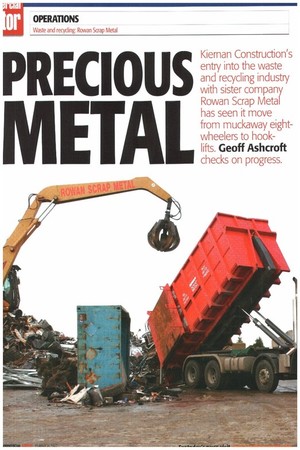

Kiernan Construction's entry into the waste and recycling industry with sister company Rowan Scrap Metal has seen it move from muckaway eight wheelers to hook

lifts. Geoff Ashcroft

checks on progress.

It has been 18 months since Kiernan Construction eased itself into the scrapmetal and recycling industry.The idea was to provide bolt-on activities to support its core business of groundworks and civil engineering.

"Our involvement in demolition and recycling on-site, along with the ability to deal with waste materials, has become increasingly prevalent through the construction side of the business," explains Kiernan's operations director, John Eccles."So we looked at finding away of developing our main activities by moving into recycling."

Rather than end up with a traditional construction-waste operation crushing and screening aggregates and shredding timber. however, the firm chose to focus on scrapmetal processing.

The result is a growing operation called Rowan Scrap Metal (RSM ),situated on a fouracre former factory site opposite the Kiernan 110 in Preston, Lancs.While the location is nevv, the fledgling venture is the former Hitchens of Chorley scrap-metal and waste-processing operation."We bought the Hitchens business from its retiring owners, gradually relocated it to Preston," says Eccles,"and made it our own."

The advantage of buying into a ready-made business has become appa rent not least because John Scott, who ran Hitchens' operation, remained with the business, "John is a great asset to RSM," Eccles explains. "With more than 30 years' industry experience and a solid relationship with many of his previous customers — who have followed him from Chorley to Preston — he has been instrumental in RSM's quick growth."

Prime location

That growth now sees around 600 tonnes of scrap metal move each way through the gates of RSM, and its industrial estate location —only half a mile from Junction 31A of the M6 —offers good infrastructure that sees the firm scatter its 130 recycling bins and skips over a wide area.

The firm is currently looking to expand into recycling white goods. "We'll run anywhere if we can make it cost-effective." explains RSM manager John Scott. "But everything we collect comes back to base for processing."

By 'everything', Scott means ferrous and non-ferrous metals. As each load comes back to base, the vehicle passes over a weighbridge before spilling its load on to a concrete pad where the contents are

but everything we collect

carefully sifted and sorted usinL the material handler.

Operating like a huge hand,the Cat M322 — with 20m boom and finger-grapple — unrave the load and segregates the metals into appropriate stockpiles for processing. While the Cat handles most of the sorting, a smaller 320 excavator has access to magnet and shear attachments to help with handling large item!

The firm also has its fair share of scrap cars, and specialist waste-processing equipment is on site to drain shock absorbers of oil, handle batteries, and store and process antifreeze and waste engine oils. RSM can prepare destruction certificates for customers and the DVLA, and has direct access to Swansea's computer for up-to-date record keeping.

Waste such as builders' rubble and timber is diverted on to other specialists who,in turn, put scrap metal in RSM's direction. "It's important to work with other specialists when it comes to dealing with non-core waste products," Scott explains.

Operating under the Kiernan Constructio: umbrella, RSM is the latest in a string of supplementary businesses that have grown out of discussions in the boardroom. While chairman Pat Kiernan and operations director John Eccles throw ideas around, the rm's finance director and Eccles' mother, me, is viewed as the sensible one who looks all angles of how a prospective business Light operate.

It's truly a family concern. June's husband atrick Kiernan started the business 35 ears ago; as well as her son being operations irector, her daughter Joanne is transport ianager.Siobhan Kiernan is the firm's health ad safety officer, while Patrick Kiernan Jr ssists in the day-to-day running of RSM longside recycling manager John Scott.A irther five family members are among the usiness's 2(X) employees.

Kiernan Construction has three additional ivisions: Rowan Environmental Training ervices, providing industry-related operator .aining; Rowan Construction Supplies, 'Tering building materials to the trade; and le latest venture, Rowan Scrap Metals. "We like to think that we treat employees a firm but fairway, with good rewards,good )nditions and open lines of communication," iys Eccles, "We've managed to hold on to perators and drivers without too much -ouble -most have been with the firm for at ;ast 10 years." more room to get comfortable."It's just nicer to drive." he says. And oft 2in colleague Paul Lane, who pilots a Scania P340 around the North-West, has to agree. 'I'd like more room in the Scania P-cab as I'm nearly sat on top of the steering wheel!" he says. "But it's the only thing I'd change -apart from adding aV8.And maybe an auto box.

Driver feedback

While not all such requests will be met with unbridled enthusiasm, the firm has time to consider constructive feedback each truck is expected to clock up around 100,000km annually during its five years on the fleet.The firm is evaluating its truck choice over the next couple of years, but hints at a Volvo FM joining the fleet.

"These guys spend their working days in the cabs, so it's important to learn what they like and dislike," says Scott."We bought our first Scania on an 05plate to supplement some of the kit that came with Hitchenshut since then, we've pushed on with updating and expanding the fleet."

The task of collecting metals currently falls squarely to four eight-wheelers with hook-lift body systems. Three are Scania P340s while the fourth is the Daf CF85.340. Each deals with RSM's collection of 70 RO-RO bodies ranging in size from 20 to 55yd3.

Rather than buy new trucks during the growth stage of the business, h owever, the firm came across three pre-registered 06-plated models, complete with hook-lifts, which hadn't turned a wheel. A deal was done and around £30,000 was saved against buying brand newThe firm also has a Daf CF 6x2 with beavertail and crane which is used primarily by the building supplies operation, but can be called in to help with recycling duties. "The biggest problem we have is with punctures," Scott points out. "It's a reflection of where we have to place bins for customers -there are times when you're backing under a bin off-road and you've no idea what surface the tyres are on. We run Goodyears, which seem to stand up to punishment quite well."

The fleet is also dual-branded, with two trucks sporting the RSM name and two carrying the more familiar Kiernan Construction logo."Kiernan is currently the stronger identity, so we're making full use of it to help establish the RSM-brand," says Scott.

In addition to RSM's high-capacity bins, there are 60 regular 8yd3 skips, which are ferried around the North-West using a 1989model Mercedes 1617.

"The Mere is a cherished truck; during its 18-year history, it has spent only the last three years on the road — the only mileage it did before that was to and from the MoT station," says Scott. It is still liveried in the former owner's colours.The 1617 has only covered 250,000km, but is proving invaluable on local skip duties.

Fleet investment l he white-liveried new truck fleet is testament to the investment being put in to develop the business. Two P-plate Seddon Atkinsons and the Merc 1617 were included in the Hitchens sale; one Seddon has been moved out while the other, a Strato 325, has been taken off the road and is being used as a bin-shunter on permanent yard duties "It's been a great excuse to get out of tippers on the construction side," says Eccles. "Our Maggie Deutzes were only good for about 3.5mpg and spent their time running one way empty. For us,muckaway tippers were a mug's game — if we need tippers now, we'll hire them in to meet our muck-shifting needs. At least with the hook-lifts we spend more time running around laden."

Though Eccles confirms that scrap metal payloads, until recently, have been poor, he compares loading the bulk bins with compressing spring. You can't get much weight into the bins unless you compress the load —which isn't much use when you need to process and separate the different metals after the load arrives back at the yard," he points out.As a result, fuel figures have been up in the high nines with relatively light, but full-volume, payloads The hook-lift kit robs each truck of valuable payload — Eccles says they're about 1,5 tonnes down on payload compared with muckaway tippers.

"Getting a decent load into a metal bin has been a challenge," he says."The most we're ever going to carry is 16 tonnes, but we're lucky to get nine tonnes on board given the nature of the material being carried. You tend to carry a significant volume of air because you can't pack scrap metal very tightly when it's coming in for sorting."

It's a different matter for outgoing metals now that the firm has invested in a £300,000 metal baler.'The compacted sled packages enable the trucks to run at full weight on the outbound journey to Liverpool docks, where processed metal is exported.

"Fuel figures have dropped to around 8mpg but we're much more productive with a full payload," says Eccles.

As compressed metal packages are churned out of the baler, they are carefully stacked ready for loading.The Seddon shunter works tirelessly ferrying bins around the yard, preparing full-weight loads and sorting them so that RSM's four front-line eight-wheelers can quickly swap bins.They stay out on the road, running export material on a 40-mile one-way journey to Liverpool docks.

"The hook-lift system is quick and easy to use, and means we can keep the fleet out on the road as much as possible, to maximise speed and efficiency," Scott explains. "If the trucks aren't collecting bins, they're not earning us money." •