SETTING UP TELEGRAPH POLES BY LORRY.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a Remarkable Adaptation of the F.W.D. Chassis which Enables It to Bore 30-in. Diameter Holes to a Depth of 10 ft. in Anything but Rock.

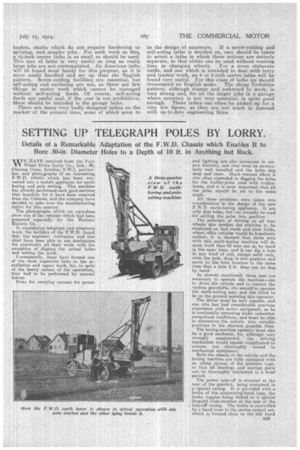

WE HAVE received from the Four Wheel Drive Lorry Co, Ltd.' 46, Charing Cross, London, S.W.1, particulars and photographs of an interesting F.W.D. vehicle which has been converted into a mobile appliance for earth boring and pole setting. This machine has already performed such good services that inquiries for it have been received from the Colonies, and the company have decided to take over the manufacturing rights for this country.

The photographs which we reproduce show one of the vehicles which had been prepared especially for the Western Electric Co.

In considering telegraph and telephone -work, the builders of the F.W.D. found that the engineer, contractor and line chief have been able to use mechanism for practically all their work with the exception of digging the actual holes and setting the poles.

• Consequently, these have formed one of the most expensive links in the installation and repair work, for, in spite of the heavy nature of the operations, they had to be performed by manual labour.

Poles for carrying current for power and lighting are also numerous in certain districts, and they must be particularly well installed and the holes dug deep and clean. Much manual effort is also often expended in digging the holes for the trolley-poles used with trolleybuses, and it is most important that all the poles should be set to the same angle.

All these problems were taken into consideration in the design of the new F.W.D. earth-boring appliance. It not only digs holes, but UM actually be used for setting the poles into position. The principle of driving on all four wheels also enables the machine to be employed on bad roads and even fields, where other vehicles would be hopelessly stalled; it is claimed that three men with this earth-boring machine will do more work than 60 men can do by hand in the same time, and it can dig a hole in any kind of soil, except solid rock, raise the pole, drop it into position and move to the next location in the same time that a hole 2 ft. deep can be dug by hand.

As already mentioned, three men are • necessary to operate the machine—one to drive the vehicle and to control the various gearshifts, the second to operate the earth-boring part and the third to be on the ground assisting this operator.

The driver most be very capable, and one who has had considerable previous experience with motor equipment, as he is continually operating under somewhat exceptional conditions, and must be able to manceuvre the vehicle into suitable positions in the shortest possible time.

The boring-machine operator must also be a good meaanic, for, although very strongly constructed, the driving mechanism would appear complicated to anyone not thoroughly versed in mechanical equipment. Both the chassis of the vehicle and the boring machine are fully equipped with an oiling system of the pressure type, so that all bearings and moving parts can be thoroughly lubricated in a brief period.

The power take-oil is situated at the rear of the gearbox, being contained in a special casing. It is provided with a brake of the contracting-band type, the brake toggles being bolted to a special dropped cross-member at the rear of the fake-off casing. The brake is controlled by a hand lever in the centre control set, which is located close to the left hand of the driver. This brake is used in connection with the boring machine only, its greatest value being for control of the winch when handling large, heavy poles.

The frame of the boring machine is rotatably -arranged on a turntable, which makes it possible to bore holes at either side or at the Fear of the brake a locking device being provided to hold the frame with the auger in position.

The turntable is operated by power, and it requires only 15 sees, to turn it from one extreme position to the other.

A worm gear is provided for tilting the tower to any desired angle for boring anchor holes, as it is almost as important to use power for this section of the work as to speed up the actual digging of the main holes for the poles.

When the vehicle is being moved from place to place, the auger tower is tilted towards the driver's seat, which reduces both the height of the whole appliance and that of the centre of gravity.

In the case of the machine for central station work, this being the largest made, the height with the tower folded is 10 ft. 8 ins., and with the tower raised 18 ft. 6 ins., and a derrick is provided for handling long poles. The sheave on the derrick is 28 ft. from the ground, and this additional appliance is carried at the side of the vehicle and projects 6 ft. 4 ins, behind the rear of the machine-when assembled for transportation, the overall length of the chassis with the derrick folded being 28 ft... When the power take-off, previously referred to, is disengaged or in the neutral position, the front end of a jaw clutch is fully engaged with the silent chain upper sprocket of the centre differential gear, which is one of the leading features of the F.W.D. design. Thus, when any gear is brought into engagement, the transmission main shaft will turn the silent chain, thereby applying power to the front and rear axles.

When the take-off is engaged for operating the earth-boring machine, the sliding jaw clutch is pushed away from the chain sprocket, and the other side is engaged with the shaft of the boring machine, the power being then transmitted from the transmission shaft to

this machine, the silent chain sprocket remaining stationary. Our illustrations give an idea of the general arrangement of the machine and of the various drives by chains and gears to the different mechanisms controlling the rotating of the turntable, the driving of the auger and the windlass for lifting the poles. The central-station machines are equipped with 24-in. and 30-in, augers, and holes 10 ft. deep can be drilled in level ground.

In what is known as the Bell-systemtype boring machine, the capacity is smaller, and the machine will bore 7 ft. deep on level ground and will set 35-ft. poles instead of those measuring 65 ft., whilst the augers are 20 ins. and 24 ins.

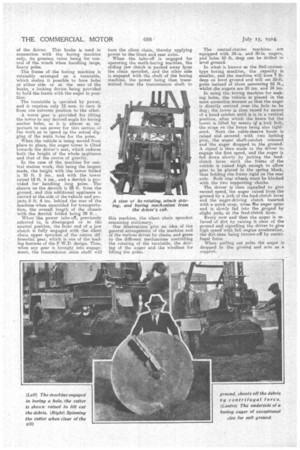

In using the boring machine for making holes, the vehicle is placed in the most accessible manner so that the auger is directly centred over the hole to be dug; the _tower is then raised by means of a hand ratchet until it is in a vertical position, after which the brace for the tower is lifted by means ot 4, lock bolt, the stops on the brace being also tightened. Next the cable-sheave boom is raised and secured with two locking pins, the auger shaft-ratchet released and the auger dropped to the ground. A signal is then made to the driver to engage the first speed, and the auger is fed down slowly by jerking the feedclutch lever until the frame of the vehicle is raised high enough to allow pins to be placed in the spring block, thus holding the frame rigid on the rear axle. Both rear wheels must be blocked with the two supporting chocks.

The driver is then signalled to give second speed, the auger raised from the ground by a jerk of the feed-clutch lever and the auger-driving clutch inserted with a quick snap, when the anger spins and is slowly fed into the ground by slight jerks at the feed-clutch leer.

Every now and then the auger is relieved of dirt by raising it dear of the ground and signalling the driver to give high speed with full engine acceleration, the dirt then being thrown off by centrifugal force.

When pulling out poles the auger is dropped to the ground and acts as a support.