Van bodies outlive two chassis or more

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

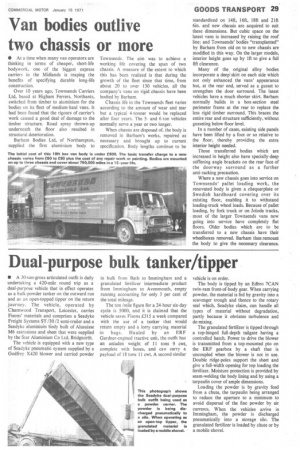

• At a time when many van operators are thinking in terms of cheaper, short-life bodywork, one of the biggest express carriers in the Midlands is reaping the benefits of specifying durable long-life construction.

Over 10 years ago, Townsends Carriers Ltd, based at Higham Ferrers, Northants, switched from timber to aluminium for the bodies on its fleet of medium-haul vans. It had been found that the rigours of carrier's work caused a good deal of damage to the timber structure. Road spray thrown-up underneath the floor also resulted in structural deterioration.

Barham Bodies Ltd, of Northampton, supplied the first aluminium body to Townsends. The aim was to achieve a working life covering the span of two chassis. A measure of the extent to which this has been realized is that during the growth of the fleet since that time, from about 20 to over 130 vehicles, all the company's vans on rigid chassis have been bodied by Barham.

Chassis life in the Townsends fleet varies according to the amount of wear and tear but a typical 4-tonner would be replaced after four years. The 5and 6-ton vehicles normally serve a year or two longer.

When chassis are disposed of, the body is removed in Barham's works, repaired as' necessary and brought up to current. specification. Body lengths continue to be standardized on 14ft, 16ft, 18ft and 21ft 6in, and new chassis are acquired to suit these dimensions. But cubic space on the latest vans is increased by raising the roof line; and Townsends' bodies "transplanted" by Barham from old on to new chassis are modified in this way. On the larger models, interior height goes up by lft to give a full 8ft clearance.

Many of the, original alloy bodies incorporate a deep skirt on each side which not only enhanced the vans' appearance but, at the rear end, served as a gusset to strengthen the door surround. The latest vehicles have a much shorter skirt. Barham normally builds in a box-section steel perimeter frame at the rear to replace the less rigid timber surround. This braces the entire rear and structure sufficiently, without gusseting below floor level.

In a number of cases, existing side panels have been lifted by a foot or so relative to the floor, thereby providing the extra interior height needed.

Those transferred bodies which are increased in height also have specially-deep stiffening angle brackets on the rear face of the doorway surround as a further anti-racking precaution.

Where a new chassis goes into service on Townsends' pallet loading work, the renovated body is given a chequerplate or Swedish hardboard covering over its existing floor, enabling it to withstand loading-truck wheel loads. Because of pallet loading, by fork truck or on Joloda tracks, most of the larger Townsends vans now going into service have completely flat floors. Older bodies which are to be transferred to a new chassis have their wheelboxes removed. Barham then remount the body to give the necessary clearance.