Take a piggyback to the future

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

• Government support for railfreight is gathering momentum. Transport Secretary Dr Brian Mawhinney wants to "spell out the realistic options for transferring freight from road to rail". The options include a literal transfer of road trailers to rail, or piggybacking,

As reported (CM 8-14 Dec) the group promoting this idea, the Piggyback Consortium, has been given the go-ahead from Rai1track. The consortium was set up in last year, following the building of the Channel Tunnel, to examine the possibility of taking long-distance loads off the road and on to rail.

Modifications It was found that a standard 4m-high road trailer could be carried on the British tracks with minimal modifications using a special rail wagon. The top of the piggyback trailer will be higher than a standard train SO some bridges will have to be raised and track lowered to

accommodate the extra height.

The consortium estimates this will cost £70m. Railtrack has been persuaded that this price is accurate and the project is viable. If the project runs on time, standard trailers will be travelling across Europe's rail network some time in 1997.

Mike Garratt of MDS Transmodal, who was involved in the original costing, suggests that up to 400,000 trucks a year could be taken off Britain's roads by the end of the decade. But given that British hauliers are often slow to adapt to new working practices, these figures have to be questioned.

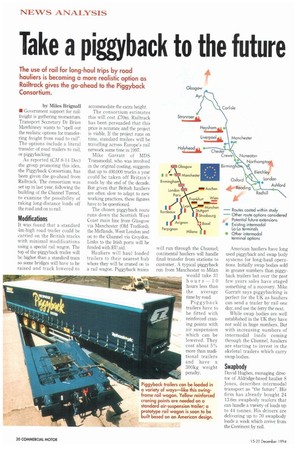

The chosen piggyback route runs down the Scottish West Coast main line from Glasgow via Manchester (Old Trafford), the Midlands, West London and on to the Chunnel via Croydon. Links to the Irish ports will be funded with EU aid.

Hauliers will haul loaded trailers to their nearest hub where they will be craned on to a rail wagon. Piggyback trains

will run through the Chunnel; continental hauliers will handle final transfer from stations to customer. A typical piggyback run from Manchester to Milan

would take 31 hours—l0 hours less than the average time by road.

Piggyback trailers have to be fitted with reinforced craning points with air suspension which can be lowered. They cost about 5% more than traditional trailers and have a 300kg weight penalty. American hauliers have long used piggyback and swap body systems for long-haul operations. Initially swap bodies sold in greater numbers than piggyback trailers but over the past few years sales have staged something of a recovery. Mike Garratt says piggybacking is perfect for the UK as hauliers can send a trailer by rail one day, and use the ferry the next.

While swap bodies are well established in the UK they have not sold in huge numbers. But with increasing numbers of intermodal loads coming through the Chunnel, hauliers are starting to invest in the skeletal trailers which carry swap bodies.

Swapbocly

David Hughes, managing director of Aldridge-based haulier S Jones, describes intermodal transport as "the future". His firm has already bought 24 13.6m swapbody trailers that can handle a variety of loads up to 44 tonnes. His drivers are delivering up to 70 swapbody loads a week which arrive from the Continent by rail.