by Bryan Jarvis

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

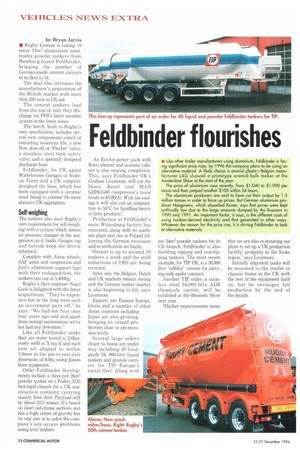

• Rugby Cement is taking 10 more 34m3 aluminium semitrailer powder tankers from Hamburg-based Feldbinder, bringing the number of German-made cement carriers in its fleet to 54.

The deal also increases the manufacturer's penetration of the British market with more than 220 now in UK use.

The cement tankers load from the top or tail; they discharge via FFB's latest aeration system in the lower cones.

The batch, built to Rugby's own specification, includes several new components aimed at extending in-service life: a new flow shut-off or 'Pincher' valve; a stainless steel tank safety valve; and a specially designed discharge hose.

Feldbinder, its UK agent Waterhouses Garages of Stokeon-Trent and a UK supplier designed the hose, which has been equipped with a ceramic inner lining to counter the more abrasive UK aggregates.

Sett-weighing

The tinkers also meet Rugby's own requirement for self-weighing with a system which senses air pressure changes in the suspension as it loads. Gauges top arid bottom keep the driver informed.

Complete with Alcoa wheels, SAF axles and suspension and Jost's aluminium support legs with their reshaped feet, the tankers tare out at 5,400kg.

Rugby's fleet engineer Nigel Cook is delighted with the latest acquisitions: "They're expensive but in the long term such an investment pays off," he says. "We had our first ones four years ago and and apart from normal maintenance we've not had any downtime."

Like all Feldbinder tanks they are water tested to 2.6bar, every weld is X-ray'd and each axle set aligned to within 1.0mm in the pin-to-rear-axle dimension of 8.0m, using Josam laser equipment.

Other Feldbinder developments include a three-pot 26m3 powder tanker on a Foden 3335 8x4 rigid chassis for a UK construction company carrying mainly lime dust. Payload will he about 22.5 tonnes. It's based on short sub-frame sections and has a high centre of gravity but its real aim is to solve the company's site access problems using artic tankers.