• Every manufacturer, spurred on by a ceaseless tide of

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

environmental legislation, has been working to make its trucks quieter — and now they are about to add a powerful hi-tech weapon to their armoury in the fight against noise.

Inevitably, the latest moves involve computers: work is well advanced on a radical technique which actually generates one sort of noise to cancel out another.

The name of the game is Electronic Noise Cancellation (ENC).

FIELD TRIALS

Detroit Diesel in association with Noise Cancellation Technologies and Walker Manufacturing, the US exhaust maker, will shortly begin sustained field trials of the ENC technology they have been developing since 1989 around Detroit Diesel engines. Their version of ENC is aimed at military and agricultural customers, as well as truck and bus operators; they are currently seeking funding from a number of governments and military forces.

Active noise cancellation is not new: the concept of ENC dates back to the 1930s. But it has taken many years for the necessary materials and electronics technology to catch up with the theory and turn it into reality.

Like most good ideas the theory is simple; only the electronics are complicated.

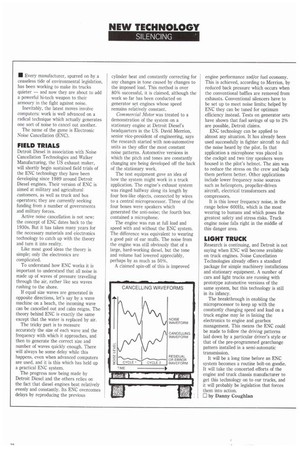

To understand how ENC works it is important to understand that all noise is made up of waves of pressure travelling through the air, rather like sea waves rushing to the shore.

If equal size waves are generated in opposite directions, let's say by a wave machine on a beach, the incoming wave can be cancelled out and calm reigns. The theory behind ENC is exactly the same except that the water is replaced by air.

The tricky part is to measure accurately the size of each wave and the frequency with which it approaches, and then to generate the correct size and number of waves quickly enough. There will always be some delay while this happens, even when advanced computers are used, and it is this which has held up a practical ENC system.

The progress now being made by Detroit Diesel and the others relies on the fact that diesel engines beat relatively evenly and constantly. Its ENC overcomes delays by reproducing the previous cylinder beat and constantly correcting for any changes in tone caused by changes to the imposed load. This method is over 80% successful, it is claimed, although the work so far has been conducted on generator set engines whose speed remains relatively constant.

Commercial Motor was treated to a demonstration of the system on a stationary engine at Detroit Diesel's headquarters in the US. David Merrion, senior vice-president of engineering, says the research started with non-automotive units as they offer the most constant noise patterns. Automotive versions in which the pitch and tones are constantly changing are being developed off the back of the stationary work.

The test equipment gave an idea of how the system might work in a truck application. The engine's exhaust system was ringed halfway along its length by four box-like objects, connected by wires to a central microprocessor. Three of the four boxes were speakers which generated the anti-noise; the fourth box contained a microphone.

The engine was run at full load and speed with and without the ENC system. The difference was equivalent to wearing a good pair of ear muffs. The noise from the engine was still obviously that of a large, hard-working diesel, but the tone and volume had lowered appreciably, perhaps by as much as 50%.

A claimed spin-off of this is improved engine performance and/or fuel economy. This is achieved, according to Merrion, by reduced back pressure which occurs when the conventional baffles are removed from exhausts. Conventional silencers have to be set up to meet noise limits; helped by ENC they can be tuned for optimum efficiency instead. Tests on generator sets have shown that fuel savings of up to 2% are possible, Detroit claims.

ENC technology can be applied to almost any situation. It has already been used successfully in fighter aircraft to dull the noise heard by the pilot. In that application a microphone was placed in the cockpit and two tiny speakers were housed in the pilot's helmet. The aim was to reduce the stress on the crew and help them perform better. Other applications include lower frequency noise sources such as helicopters, propeller-driven aircraft, electrical transformers and compressors.

It is this lower frequency noise, in the range below 600Hz, which is the most wearing to humans and which poses the greatest safety and stress risks. Truck engine noise falls right in the middle of this danger area.

LIGHT TRUCK

Research is continuing, and Detroit is not saying when ENC will become available on truck engines. Noise Cancellation Technologies already offers a standard package for simple machinery installations and stationary equipment. A number of cars and light trucks are running with prototype automotive versions of the same system, but this technology is still in its infancy.

The breakthrough in enabling the microprocessor to keep up with the constantly changing speed and load on a truck engine may lie in linking the electronics to engine and gearbox management. This means the ENC could be made to follow the driving patterns laid down by a particular driver's style or that of the pre-programmed gearchange pattern installed in a semi-automatic transmission.

It will be a long time before an ENC system becomes a routine bolt-on goodie. It will take the concerted efforts of the engine and truck chassis manufacturer to get this technology on to our trucks, and it will probably be legislation that forces them into action.

0 by Danny Coughlan