An Anti-vibration Engine Mounting

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

THE absorption of engine vibration by means of rubber mountings is now general practice in the design of .commercial vehicles. A mounting known as the Floatex, and embodying the Silentbloc patents, is produced by Andre (Silentbloc), Ltd, Victoria Gardens, Ladbroke Road, London, W.11, and this system is standardized by several well-known makers.

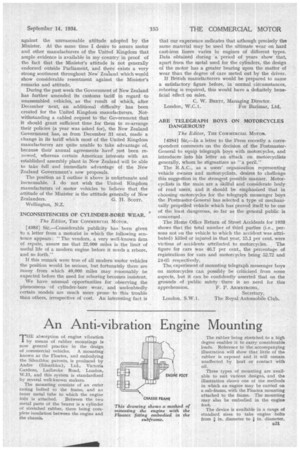

The mounting consists of an outer casing bolted to the frame, and an inner metal tube to which the engine 106t is attached. Between the two metal parts of the bearer is a cylinder of stretched rubber, there being complete insulation between the engine and the chassis.

This drawing shows a method of mounting the engine with the Floater fitting embodied in the subfrante. The rubber being stretched to a high degree enables it to carry considerable loads. Reference to the accompanying illustration will show that little of the rubber is exposed and it will remain unaffected by heat or contact with oil.

Three types of mounting are available to suit various designs, and the illustration shows one of the methods in which an engine may be carried on a sub-frame, with the Floater mounting attached to the frame. The mounting may also be embodied in the engine foot.

The device is available in a range of standard sizes to take .engine bolts from in. diameter to in. diameter. n31