POWDERS IN BULK A Challenge tc Road Hauliers

Page 78

Page 79

Page 80

Page 81

Page 82

If you've noticed an error in this article please click here to report it so we can fix it.

AWELL-KNOWN manufacturer who uses a wide variety of granulated materials and powders has postponed the introduction of bulk delivery pending an investigation of the handling equipment available and the facilities offered by road and rail transport. Whether the materials will be carried by road or rail depends on matching the most appropriate type of equipment to the transport service that can best cater for it.

This summary typifies the projects of an impo-.-tant minority of producers, who are seriously analysing the possibilities of bulk transport for materials that are mainly carried in packages at present. It also indicates . one of the many problems that face the makers of bulk-handling equipment and of vehicles that could be employed for the traffic,

Certain commodities have for years been trans ported 'in. bulk and the vehicles and systems used have been widely publicized. In many cases, however, the economics of an individual application of the method are so complex that failure on the part of the operator to appreciate all the implications can result in a serious financial loss.

The low discharge height of a hopper on the premises of one of a number of traders, whom I visited could, for example, necessitate the subeconomic use of a modified form of equipment. Again the need to provide against a rare breakdown may give an advantage to a less efficient method because of the ready availability of replacement vehicles.

In another instance, the angle of repose of the material carried may be increased by a humid atmosphere, or a change in composition, to an extent which prevented its easy discharge. Traders are often unwilling to disclose the arrangements made to load and discharge bulk vehicles because to do so would benefit their competitors. Rebuilding existing premises to provide storage must be closely related to the type of vehicle used, if capital expenditure is to be reduced to a minimum, and this may be decided by the method of loading.

A challenge to hauliers is contained in the comments of a supplier of constructional materials with a particular interest in bulk transport. He told me that many small traders had to sutler financial loss by buying expensive specialized vehicles to meet the demand of customers for bulk delivery.

A haulier, or group of hauliers, who can cater for the requirements of a number of small traders represents a valuable asset and the service may in an extreme case enable a trader to avoid absorption by a larger competitor.

The supplier mentioned above emphasized the importance of investigating alternative means for loading bulk vehicles to reduce the cost of storage equipment, and to enable different types of vehicle to use a variety of loading bays, or to operate independently. He also advocated the more extensive• employment of bulk semitrailers to provide mobile temporary storage containers without immobilizing the prime mover.

ALTHOUGH developments in the bulk delivery of animal food in the past 18 months have not been accepted on a large scale by farmers, many of the

methods employed have been of interest to users, and potential users, of bulkhandling equipment in other industries.

For example, operators and traders have been considering whether the straddle-leg method of loading and unloading laden silos developed by members of the staff of Harper Adams College and Staffordshire Farmers, Ltd., which was demonstrated last July, could have important industrial applications.

The future of the demountable container is probably the most controversial aspect of bulk haulage.' Developments in the next few years may be critical, as established storage facilities cannot easily be converted to cater for another system.

• Evidence from America show S that containers can be employed advantageously on traders' premises for storage • and internal movements, but this may not justify the abandonment of an existing method of handling. To the haulage operator, the outstanding merit of demountable containers is that a standard platform lorry can be employed for their transport.

• Although the necessity to return empty containers normally restricts the use of the vehicle for carrying other 'back-loads, it should be possible to organize a separate return-load service to enhance the overall efficiency of vehicle operations if large quantities of material were regularly carried by this method.

r1IRST developed in America, the Tote Bin system is based on the use of light-alloy sealed containers. These are produced in this country in capacities of 42 cu. ft., 74 cu. ft. and 110 cu. ft. by Pressoturn, Ltd., Leamington Spa. The bins are conveniently handled by fork-lift truck. Easy discharge in the factory is facilitated by a tilt unit, which• can be equipped with a screw conveyor for delivery to a production plant.

Recent applications of the Tote 13in system include the carriage of carbon D10 black from Ellesmere Port to Wolverhampton for the Goodyear Tyre and Rubber Co. (Great Britain), Ltd., by Parkfield Transport, Ltd. Eight containers are carried on a !wry and, although transport by this means is in the experimental stage, it is likely to be applied on a larger scale later.

Traders in Sweden are reported to be planning a more widespread use of containers than manufacturers in Great Britain. This is substantiated by advice from Aktiebolaget Findus, of Bjuv, that carrying granulated sugar for a Swedish sugar company in Tote Bins will provide a definite saving in transport costs.

It is thought that baby food, cake mixes, starch and salt will also be delivered in containers in increasing quantities, and projects are being evolved to employ containers far more extensively for the direct export of home-produced materials on motor vehicles. Special rail trucks have been developed in America specifically for carrying Tote Bins.

An important opinion on the development of container traffic came from a spokesman of Unilever Ltd., Unilever House, London, E.C.4. He said that the use of vehicles carrying demountable pressurized containers was being investigated. Possible applications. were the carriage of materials between premises on which the filling or discharge point was normally inaccessible.

The techniques of handling commodities in bulk are constantly under review

• by the Unilever group of companies and attention has been focused on the transport of powdered and granular chemicals between the supplier and factory. An interesting variation of the demountable-container system for bulk transport, the application of which has so far been limited to animal foods, has been developed by Nerinett Handling Equipment, Ltd., Bury St. Edmunds. In standard form, this comprises four separate containers mounted on a platform lorry, which can be tilted for discharge of the material by hand-operated hydraulic jacks or raised vertically by the jacks in order to attach support legs.

DNEUMATIC discharge has an advantage in the delivery of any material •in that the vehicle can be located near the storage. bin, rather than in one exact position. A similar latitude with regard to loading would simplify many applications of bulk. handling.

The Gobler wheat backloader developed by Bulkrnobile, Ltd., Great Cornard, Sudbury, for use with the Bulkmobile animal-food carrier, shows a novel application of this principle in the form of an oil-driven auger flexibly, connected to the ,hydraulic system of the vehicle, which delivers the grain into a pneumatic line. The material is discharged through a duct in the .top of the body.

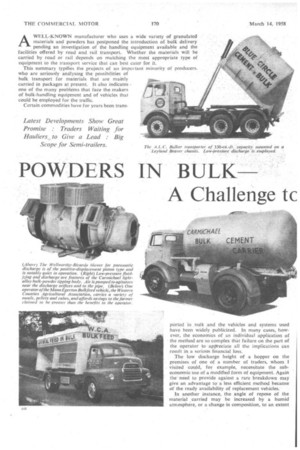

The Bulkmobilc isa good example of a general-purpose vehicle which can be used for carrying sacks or for normal tipping operations if not required for bulk transport. A particular feature is a hydraulically operated rotary seal. The body is tipped to discharge a bulk load and the material is fed by a doubleworm auger to the seal which . communicates with an air-pressure discharge A Duramin light-alloy body helps to offset the weight , of the mechanical equipment. The auger is removed if the vehicle is used for other operations. An alternative method is aeration of the material in a pressurized container body and discharge by compressed air. This •has been adopted by a number of makers for many powdered and granulated materials and is found in the bulktransport 'equipment produced by Carmichael and Sons (Worcester); Ltd., The Butts, Worcester. This equipment is now employed extensively for the transport of cement, notably by the Rugby Portland Cement Co.,. Ltd:, Hall and Co., Ltd., .Ribblesdale, Cement,..Ltd., and the Associated Portland Cement Co.; :Ltd, It can be adapted to the carriage of Pulverized fuel. flour, grain, and limestone powder, users in this category including the Witney and Jlardwiek Lime Co., ,Ltd.

Discharge is assisted in the .ease of the Carmichael body by ,tipping, and advantages of the system include the elimination of mechanical gear, apart from the blower and tipping gear. The body is of light alloy.

Division of the load into a number of separate compartments has obvious advantages for mixed deliveries of animal food. The . Bulkfeed four-compartment hopper 'vehicle produCed by Mann Egerton and Co., Ltd., Norwich, cornbines this feature with a full-length screw conveyor which feeds the material to an • air • line through a rotary seal.

The transport manager of Western Counties Agricultural Association, Ltd., • Redcliffe Wharf, Bristol, said that bulk handling with such a vehicle reduced turn-round time by 30 minutes and that hulk delivery enabled the, .driver to unload the vehicle without assistance. major problem that may hamper its more general introduction for many years.

Many smaller builders are also reluctant to apply bulk handling methods, but according to the transport engineer of Hall and Co., Ltd., Redhill, Surrey, bulk 'transport will cover up to half the cement supplied in the next year or two.

Hall's employ low-pressure charge systems . produced by the Amalgamated Limestone Corporation, Ltd., 15 Stanhope Gate, ,London, W.1, in addition to the equipment supplied by Carmichael's. A change-over from high to low-pressure operation followed adop-. tion of the system by a large number • of 'cement manufacturers.

4 feature of the Carmichael vehicles is the optional • use of WeliworthyRicardo positive-displacement blowers of the piston type produced by Weliworthy, Ltd., Lymington, Hants, which operate at a higher speed than the Roots type, but are much quieter in operation and deliver oil-free air. • The elimination of. piston friction is particularly advantageous.

Resistance by farmers to bulk handling has frustrated the attempts of Watts and Sons (Banbury), Ltd., Oxon, to introduce this form of delivery for cattle, poultry and pig foods, arid the development of a particularly interesting prototype bulker has been delayed. This vehicle was evolved by the Northern Aluminium Co, Ltd., Banbury, who sought to produce a type • between the highly specialized vehicle and the tipper.

The 6-ton light-alloy body.. is shaped in the form of a hopper, but has a .central flat section in the base. A. continuous

rubber belt conveys the material to a belt-paddle elevator at the rear, mounted in a hinged light-alloy structural member. Belt drive is provided by a shaft connected to the powertake-off, which operates a gearbox in line with the rear roller, the elevator being driven by a

chain and sprocket. . . .

The elevator, which can be. easily raised by one man, facilitates deliveries of grain to small Millers because it can readily be placed for discharge into the normal sack intake. It is estimated that the equipment, if developed to the production stage, would be. about £500 cheaper than more conventional plant

CJ UMMARIZING the complex prob0 /erns associated with the bulk transport of powders, a director of the Yorkshire Engineering and Welding Co. (Bradford), Ltd., Idle, Bradford, referred to the "enormous variation in the weight, particle size, shape and dryness fraction of different materials " and to the marked extent that traders' custom and convenience determined the size and type of vehicle employed.

Equipment currently supplied to operators includes a 6-ton two-compartment tipping vehicle eqaipped with a rotary seal and pneumatic .discharge system, which can be employed for carrying sacked loads in addition to flour, pellets and cubes in bulk.. .A twin-vessel salt carrieremploys high-pressure discharge and an internal lining is fitted to resist chemical attack.

Air-slide fluidizing units enable the three vessels•of a bulk-fldur.vehicle to be discharged separately, and a semi-trailer is used for a pressure-type three-vessel carrier, which-is suitable for fluorspar and other heavy powders.

Future developments, the' general • manager of the company said, might be centred on the more accurate control of discharge, including the mixing of materials from a number of separate vessels. Besides advances in the application of self-loading mechanisms, -the ejection of measured quantities might be possible. Increasing use of light, alloys and stainless steel for the container vessels was also forecast.

All the A.L.C. transporters produced by the Amalgamated Limestone Corporation are of the low-pressure discharge type, and tipping gear provides gravity feed to the tapered outlet. The maximum air pressure is 10 p.s.i. and the pressure vessel is of lightweight all-welded aluminium construction. Oil-free air is delivered by the blower, an important operational feature when dry powders are carried.

Included in the powders for which equipment has been supplied, dry pulverized fuel ash is loaded and discharged without the escape of dust. It is claimed that the dust of this very fine powder is particularly difficult to eliminate if the material is sacked or carried in other types of bull( equipment.

AVA1LABILITY of temporary storage facilities may be the deciding factor as to whether deliveries can be made in bulk. The Dumbo self-erecting hopper made by the same concern reduces the cost of providing storage on building sites and so on to a minimum. It is of all-steel construction and can be carried on a platform lorry.

Unloading and loading of the empty hopper are performed with the aid of a built-in winch. No foundations are required. The hopper has a capacity of 20 tons, and auxiliary features include a measuring device which is of special importance in the production of concrete. It is equipped with an efficient air filter to prevent the escape of dust.

Built for a Norwegian company by R. A. Dyson and Co., Ltd., Grafton Street, Liverpool, 8, a self-discharging hopper type integral semi trailer is apparently of straightforward design, but the structure gives a most unusual appearance and indicates that its layout has been closely matched to the particular requirements of the operator. It will be employed for the transport of cement and marks the first venture of the company into bulk handling.

Rubber sealing of the filling and discharge orifices, which are secured by small cam clamps, gives complete water proofing. Because of pipe freezing difficulties that occur under Arctic conditions with other types of vehicle equipped with two -line air pressure braking systems, electrically operated brakes are employed, which obviate condensation in the actuating gear.

Operating on the venturi principle, the blower unit of the three-hopper bulkgrain semi-trailer produced by Byron Farm Machinery, Ltd., Walthamstow, London, E.17, is driven by a petrol or ol2 oil engine of 10 b.h.p. mounted on the vehicle. The semi-trailer can, therefore, be loaded independently of the tractor, and—of equal importance in some applications—it can also be loaded pneumatically with the aid of a portable venturi unit and branch air line.

One advantage of using a semi-trailer is that the pipework is unobstructed. It is claimed that the blower can efficiently handle other materials in addition to grain, including grass cubes, beans, peas, coffee and groundnuts. The semi-trailer TN the past two years, the Lime Division of Imperial Chemical Industries, Ltd., Buxton, and the Salt Division of the company at Winsford have introduced bulk delivery of Limbux hydrated Buxton lime and dried vacuum salt, respectively, and have thereby enabled the delivered costs of the materials to be reduced. A lower cost of handling in the works is also, in many cases, an added incentive to the customer to accept the materials in bulk. Lime is carried in a 1,000-cu.-kt. body mounted on an eight-wheeler.

The elimination of causes of possible contamination is a valuable feature in the bulk 'handling of salt. It is carried in vertical pressure vessels which resist corrosion and have a capacity of 7 tons or 14 tons. The salt is pumped directly into the saturator or into a lagged and heated silo, which may be located at any reasonable height.

AANY hauliers and some C-licence Lifi operators are keenly concerned about the possibility of extended opportunities of back-loading. The trend of current designs of bulk carriers is such that the use of specialized features may increasingly restrict back-loading. The problem may, however, be solved in the case of .a substantial proportion of the commodities now carried in bulk or which will soon be handled in bulk.

" Because of the specialized nature of the types of bulk vehicle at present in use," said a Unilever executive, " the ratio of tare weight to payload and loaded mileage to empty mileage have been receiving considerable attention.

"Applications where a pressurized vessel may be used for carrying one commodity in one direction and another on the return journey would seem to be somewhat limited, although the use of non-pressurized. dual-purpose vehicles for the interchange of bulk or packaged goods appears in certain circumstances to be a practical proposition.

"There is, however, the point that, whereas the C-licence user is restricted to carrying his own commodities, which, as to tonnage and location, may not be complementary, the A-licence haulier has the opportunity of making, full use of the potentialities of this type of vehicle."