London's Tailor-made By j At. F R . .1T on,

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Ambulance Excels

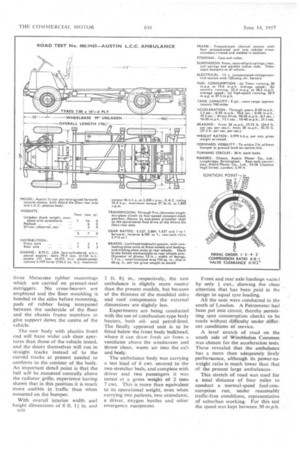

FOR many years it has been the custom of the supplies department of the London County Council, in consultation with the London Ambulance Service, to design the council's own ambulances and even build the prototypes. Their latest ambulance is also being produced at the L.C.C.'s Wandsworth depot.

By relatively simple adaptation of the well-known Austin LD.2A petrolengined 30-cwt. forward-control van chassis and the resourceful use of plastics body components, the L.C.C. have produced an ambulance which is cheaper, lighter, easier to handle, more comfortable, more manoeuvrable and more economical than anything hitherto used in London.

Credit for the design of this ambulance must go to Mr. J. D.

Burton, B.Sc., A. C. G. I., A.M.I.Mech.E., A.M.Inst.T., transport officer of the supplies department, under the chief officer of supplies, Mr. T. J. Jones, 0.B.E., assisted by Mr. W. S. Grove, M.B.E., the works foreman, and Mr. F. C. Price, body-shop foreman.

Much helpful work in the venture has also been done by the manufacturers of the original chassis and by the Allard Motor Co., Ltd., London, S.W.4, who have ingeniously transformed the standard Austin 30-cwt. rear axle into a low-height De Dion assembly, and' Woodhead-Monroe, Ltd., Ossett, Yorks, who supplied the new springs and dampers.

Subject to satisfactory service trials of the prototypes, it is probable that more of these ambulances will be built to replace the larger ambulances D8 in the existing L.C.C. fleet. Some of these may be powered by the B.M.C. 2.2-litre oil engine for sitting-case and other non-emergency work. The use of similar chassis for 12-seat school-bus bodies is also under consideration.

The new ambulance was described in the March 22 issue of The Commercial Motor. At that time there were two ambulance chassis under development, one with a rigid back axle with offset differential and the other with an Allard De Dion unit.

Since then it has been decided to standardize on the De Dion unit because of the greatly improved ride given by the coil-spring suspension in comparison with that of the semielliptic springs used with the rigid axle. Twelve ambulances of this type are to be built this year.

Little original material has been wasted by the use of a De Dion axle at the rear. Allard have managed to retain the standard final-drive gearing and axle pot, wheel hubs and brakes, the inner and outer half-shaft sections and even the original springhanger brackets which now form the fulcrum points for the twin rubber.

bushed parallel radius rods used at each side of the axle.

Allard have made full use of their experience in the motor-racing field to produce this axle, and the De Dion tube which locates the hubs is similar to that employed in their racing cars, giving ample strength reserve. The axle pot is bolted to two steel plates mounted on a rubber frame, two additional tubular crossmembers having been welded to the chassis to act as sup ports for the pot.

The primary idea is to dispense with the need for bump clearance between the top of the axle pot and the underside of the body floor, and in this way it has been possible to make the floor flat and keep the loading height down to 1 ft. 8 in.

Suspension of the rear wheels is by large coil springs, assisted by

Woodhead Monroe telescopic dampers, which have a travel of 6 in. The coil springs are set well out from the sides of the frame, as are the dampers, thereby giving great antiroIl stability. Rebound cheek straps are provided around the De Dion

tube, and the two drive shafts are exposed, with Hardy Spicer universal joints at each end.

Modifications to the front end of the standard chassis include the, fitting of 44i-in.-long front springs (instead of the standard 364 in.), and the incorporation of identical dampers to those used at the rear.

Additionally, the steering column has been moved forward 3; in.. to allow the driving seat to be moved by the same amount and thus leave space for a body length of 9 ft. 5 in. within an overall length of 15 ft. This overall length is almost 4 ft. less than that ofthe large ambulances . at present in service with the L.C.C.

In other respects the chassis specification is as standard, and the general aim at simplicity is epitomized by the retention of the original four-speed constant-mesh gearbox. Independent front suspension has not been considered to justify the expense and mechanical complication.

A minor deviation from the standard _specification concerns the batteries. Two 6v. units, as fitted to the standard oil-erigined chassis, are stowed at the rear to assist in obtaining equal loading at all wheels.

Similarly, because of the low gross weight of the complete ambulance, it has been possible to use the tyres normally fitted to the 1-ton chassis, these being 7.00-16-in. (6-ply) tubeless. No spare wheel is necessary, thus saving further weight. • All the body mouldings are being made at the Wandsworth depot—a commendable venture, as about 12 months ago no plastics work had ever been undertaken there.

The main plastics body components of the ambulance tested consisted of the two sides, the roof, the sliding cab doors and the rear doors. The original Austin grille and pressed-steel front-end assembly was retained, but further ambulances are to have a one-piece plastics fronl moulding, with a deep two-piece. wrap-round windscreen and a novel radiator grille.

Another innovation not included on the test vehicle, but scheduled for future models, is a one-piece plastics floor moulding, which will include the cab floor and all wheel-arches.

Body mounting is unusual. The side panels are each supported on three Metacone rubber mountings which are carried on pressed-steel outriggers. No cross-bearers are employed and the floor moulding is bonded to the sides before mounting, pads of rubber being interposed between the underside of the floor and the chassis frame members to give support down the centre of the vehicle.

The new body with plastics front end will have wider cab door apertures than those of the vehicle tested, and the doors themselves will run in straight tracks instead of to the curved tracks at present needed to conform to the contour of the body. An important detail point is that the hell will be mounted centrally above the radiator grille, experience having shown that in this position it is much more audible in traffic than when mounted on the bumper.

With overall interior width and height dimensions of 6 ft. 1-1 in. and 5 ft. 81 in., respectively, the new ambulance is slightly more roomy than the present models, but because of the thinness of the moulded sides and roof components the external dimensions are slightly less.

Experiments are being conducted with the use of combustion-type body heaters, both oiland petrol-fired. The finally approved unit is to be fitted below the front body bulkhead, where it can draw fresh air from a ventilator above the windscreen and throw clean, warm air into the cab and body.

The ambulance body was carrying a test load of 6 cwt. secured to the two stretcher beds, and complete with driver and two passengers it was tested at a gross weight of 2 tons 7 cwt. This is more than equivalent to its operational weight, even when carrying two patients, two attendants, a driver, oxygen bottles and other emergency equipment.

Front and rear axle loadings varied by only cwt., showing the close attention that has been .paid in the design to equal tyre loading.

Alt the tests were conducted in the south of London. A Petrometer had been put into circuit, thereby permitting spot consumption checks to be made without difficulty under different conditions of service.

A level stretch of road on the south side of Wimbledon Common was chosen for the acceleration tests. These revealed that the ambulance has a more than adequately lively performance, although its power-toweight ratio is much lower than that of the present large ambulances.

This stretch of road was used for a total distance of four miles to conduct a normal-speed fuel-consumption run, under reasonably traffic-free conditions, representative of suburban working. For this test the speed was kept between 30 m.p.h. and 40 m.p.h. and the circuit was covered at an average speed of 28.5 m.p.h., the meter indicating a consumption rate of 22.4 m.p.g.

From South Wimbledon the ambulance was then driven through heavy traffic to Wandsworth, passing through Tooting, Datham and Clapham Common. Traffic was extremely heavy and count was lost of the number of times that the ambulance was brought to a standstill.

Seven miles of this course were covered, and the total time taken was 211 minutes, of which scarcely more than 5 minutes would have been spent in top gear. Nevertheless, an average speed of 19.6 m.p.h. was maintained and a con sumption rate of 20 m.p.g. returned.

This is an excellent figure for a full-sized petrol-engined ambulance and the London Ambulance Service expects to save about £40,000 per year if the new vehicles are placed in service. On the way doWn to Succombs Hill, in the Purley area, a third fuelconsumption test was made, during which I drove the ambulance at up to 50 m.p.h., wherever traffic permitted, over a reasonably open toad.

This test was made at an average speed of 37.5 m.p.h., and the con sumption rate recorded was 20.9 m.p.g., once again an excellent figure. The climb up the half-mile gradi ent of Succombs Hill, which averages 1 in 9, was made in an ambient temperature of 60° F., and at the bottom of the hill the coolant temperature was 170° F.

Fast Hill-climb

The hill, the steepness of which approaches 1 in 44, was climbed in 11 minutes, which is one of the fastest times ever recorded, and the coolant temperature rose by only 10° F. The lowest gear used was second, and between the two steepest sections it was possible to engage third gear for just over 15 seconds.

With neutral engaged and the foot brake lightly applied to restrict the speed to approximately 15 m.p.h., the hill was then descended, this taking 1 minute 10 seconds. Although there was a pronounced smell of hot facings by the time the bottom of the hill was reached an emergency application of the foot brake from 20 m.p.h. produced a Tapley meter reading of 81 per cent. There was no fade at all.

Following the stop-start tests a second descent was made with the same result, and this was sufficient to convince me that the braking area of 66 sq. in. per ton gross weight is sufficient to preclude the possibility of fade occurring even during extreme service conditions.

Returning up the hill the ainbu lance was stopped on the 1 in 5 section, where the hand brake held it easily. It was possible to make a second-gear re-start without having to slip the clutch.

Higher up the hill the vehicle was stopped on the 1 in 41 section, where, once again, the hand brake proved its effectiveness. I then attempted a second gear re-start, which understandably failed—but only just—but a bottom-gear re-start was made without any trouble with the engine running at almost idling speed.

From the performance during these tests, it is obvious that the ambulance would be able to reach any casualty, provided that there was a road of some sort, no matter what the gradient might be.

The effectiveness of the brakes when making emergency stops is shown in the data panel. As might be expected, inter-axle weight transference caused locking of the rear wheels when making these stops from both 20 m.p.h. and 30 m.p.h., but the retardation figures recorded show complete safety. Had traffic conditions permitted I would have conducted similar " crash ". stops from 40 m.p.h., or even50 m.p.h., with complete confidence, When making emergency stops from 20 m.p.h. by use of the hand brake alone, both rear wheels locked immediately the lever was actuated and an average deceleration rate of 32 per cent. was recorded. The hand brake is conveniently placed to the left of the driving seat.

The forward-visibility check merely served to prove what is apparent to anybody driving the vehicle—that the range of vision given by the forward driving position is exceptional.

The excellent forward vision is of great aid towards fast and safe driving, particularly in heavy traffic, and combines with the small turning circle of 36-ft. diameter to give the ambulance a high degree of agility.

This in turn puts far less strain on the driver, and the steering is light enough to cause no tiredness. Again, even in heavy traffic, undue gear _ changing should not prove necessary and third ratio can be used for swift acceleration from 5 to 40 m.p.h.

A feature of the original ambulance was the degree of engine induction roar which penetrated both the cab and the body. An A.C. wetgauze-type air cleaner and silencer as fitted to Austin taxicabs, has effectively cut down the roar. This filter is fitted straight on to the engine without any modification. It is hoped to be able to reduce the volume of the exhaust note also by the use of an alternative design of silencer box, and any remaining engine noise will be deadened by the plastics engine cowl of later versions.

Complete Comfort

Other than the slight gear noise in the indirect ratios, which never becomes over-pronounced, a patient travelling in the Austin ambulance cannot fail to be comfortable. The supple front springs and the excellence of the De Dion layout successfully damp out pitch, roll or bounce.

The ventilation is adequate and during day-time the' interior of the body is well lit by the translucent centre section of the plastics roof.

On the all-plastics-bodied ambulances there will be no paintwork, the mouldings being impregnated with colour during construction. This technique is also being applied to the " ambulance " and " accident " signs.

Maintenance of the ambulance will be similar to that of the standard Morris 1-ton van (The Commercial Motor, May 4, 1956), with the exception that the use of Girling brakes, makes the brake adjustment much easier and that there will be no floor trap to allow inspection of the backaxle oil level from above.