AM - ARCING

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

BACKWARDS

LAST YEAR 274 lorries, 451 light goods vehicles and 40 buses and coaches were involved in accidents while reversing.* These are just the more significant accidents that were reported to the police and collated by the Department of Transport.

There were hundreds more that were less dramatic but still caused plenty of material damage.

Here, CM looks at rear underrun bars and reversing alarms — two ways of saving lives and reducing the damage to vehicles and property.

MANY TRAILERS' rear underrun bars bear battle scars and this underlines the fact that these bars have :1 dual role.

Although the regulations governing them were drawn up around their role as a protector for motorists in rear underrun accidents, in practice they

more frequently become a -nudge bar' during reversing.

A rigid steel bar of suitable proportions (eg, hollow, square section 100x1(10mm) suffices, but there are several more sophisticated devices on the market that do more than merely meet the legal requirements. (see over).

First, there are those underrun bars designed to absorb the energy of an impact (either an underrun accident or a knock while reversing). To gain EEC Type Approval they must be able to withstand the impact of a one-tonne motor car at 48km/hr (30mph).

Because of their energy-absorbing mechanisms they carry a slight weight penalty, which is imposed on the rear axle. A conventional rigid bar and support arms for a 12.2in trailer weighs around 40-50kg, whereas the energy absorbing devices are in the 55-75kg bracket.

Second, there arc the rear underrun bars that can detect when the trailer or vehicle touches something during reversing and autoniatic-ally apply the brakes.

Either type of device incurs additional cost for the operator and so has to justify itself on the grounds of safety or reduced damage to the trailer.

Wint!fril of East Dereham, Not:jOlk, produces an underrun bar that conies somewhere in between a conventional rigid one and a full energy-absorbing device. It has a rigid bar and supports that are bolted to the trailer or vehicle, but incorporates flexible rubber bearing pads in die support brackets. These are designed to soak up minor knocks without bending any metal. Price of the bar is around 065.

Quinton Hazen Urtderider: The Underider underrun guard absorbs the energy of a rear-end collision or reversing "nudge" by means of its two hydraulic energy absorbers. They are in the two struts that support the transverse steel beam.

These sealed hydraulic units act in a progressive way so that they begin to yield in a gentle reversing knock but stiffen up to absorb the energy of a full rear underrun accident. The maximum travel of the beam is generally 300.4110mm.

A complete Underider (beam, struts and brackets) for a trailer weighs approximately 75kg. Mounting is by welding or bolting to the chassis.

Maintenance is confined to greasing the bearing pins and Quinton Hazel] says that even if the vehicle is involved in an underrun accident it should not be necessary to replace the hydraulic units. A swing-back model is available for vehicles that may encounter obstacles• that would push the beam in the opposite direction — useful for disembarking from ferries or crossing rough ground. Prices for Underider range from 4:185 to 4:300.

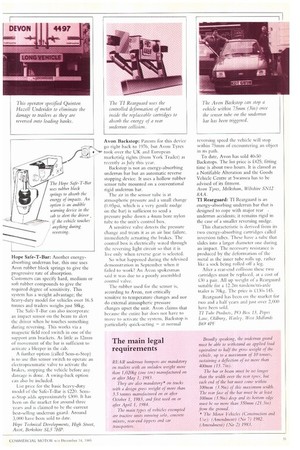

Approximately 6,00n Vnderiders have been sold. Quinton Hazel!, Hazel! House, Leamington Spa, Warwickshire C V.32 6RF. Hope Safe-T-Bar: Another energyabsorbing underrun bar, this one uses Aeon rubber block springs to give the progressive rate of absorption. Customers can specify hard, medium or soft rubber compounds to give the required degree of sensitivity. This system has a weight advantage; the heavy-duty model for vehicles over 16.5 tonnes and trailers weighs just 58kg.

The •Safe-T-Bar can also incorporate an impact sensor on the beam to alert the driver when he touches something during reversing. This works via a magnetic field reed switch in one of the support arm brackets. As little as 12min of movement of the bar is sufficient to activate a bleeper in the cab.

A further option (called Sens-n-Stop) is to use this sensor switch to operate an electropneumatic valve to activate the brakes, stopping the vehicle before any damage is done. A swing-back option can also be included.

List price for the basic heavy-duty model of the Safe-T-Bar is £220. Sensn-Stop adds approximately OM. It has been on the market for around three years and is claimed to be the current best-selling underrun guard. Around 3,000 have been sold to date.

Hope Technical Developments, High Street, Ascot, Berkshire SL5 7HP.

Avon Backstop: Patents for this device go right back to 1976, hut Avon Tyres took over the UK and European markethig rights (from York Trailer) as recently as July this year.

Backstop is not an energy-absorbing underrun bar but an automatic reverse stopping device. It uses a hollow rubber sensor tube mounted on a conventional rigid underrun bar.

The air in the sensor tube is at atmospheric pressure and a small change (0.(l5psi, which is a very gentle nudge on the bar) is sufficient to send a pressure pulse down a 41mn bore nylon tube to the unit's control box.

A sensitive valve detects the pressure change and treats it as an air line failure, immediately actuating the brakes. The control box is electrically wired through the reversing light circuit so that it is live only when reverse gear is selected.

So what happened during the televised demonstration in September when it failed to work? Au Avon spokesman said it was due to a poorly assembled control valve.

The rubber used for the sensor is, according to Avon, not critically sensitive to temperature changes and nor do external atmospheric pressure changes upset the unit. Avon claims that because the entire bar does not have to move to activate the system. Backstop is particularly quick-acting — at normal reversing speed the vehicle will stop within 75mm of encountering an object in its path.

To date, Avon has sold 40-50 Backstops. The list price is £425; fitting time is about two hours. It is classed as a Notifiable Alteration and the Goods Vehicle Centre at Swansea has to be advised of its fitment.

Avon Tyres, Melksham, Wiltshire SN12 8A A.

TI Rearguard: TI Rearguard is an energy-absorbing underrun bar that is designed to cope with major rear underrun accidents; it remains rigid in the case of a smaller reversing nudge.

This characteristic is derived from its two energy-absorbing cartridges called inversion tubes. These have a tube that slides into a larger diameter one during an impact. The necessary resistance is produced by the deformation of the metal as the inner tube rolls up, rather like a sock being rolled off a leg.

After a rear-end collision these two cartridges must be replaced, at a cost of £30 a pair. All up weight of a Rearguard suitable for a 12.2m tandem/tri-axle trailer is 70kg. The price is £130-145.

Rearguard has been on the market for two and a half years and just over 2,000 have been sold.

TI Tube Products, PO Box 13, Popes Lane, Oldbury., Warh.y, West Midlands B69 4PI: