Lightweight diesel engine

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

rotil India from a special correspondent

■ new van/car unit of 2.4 litres for world markets

RLOSKAR Oil Engines Ltd :OEL) has developed a small, htweight four cylinder iter-cooled diesel engine of kW (76bhp) rating for which oduction plans include a 3nthly output of 1000, with ternational availability early xt year. This new engine has en designed and developed tirely by KOEL, and the imary intention behind the ncept was to provide a suitle "economy" replacement r the four-cylinder petrol .gine used in Jeep utility • hides, the 2.2-litre Jeep .gine having a power rating • 54kW (72bhp).

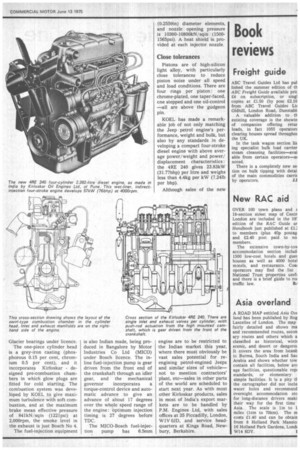

The new Kirloskar engine is iown as the 4RE 240, and it s a displacement of 2.392 res, bore and stroke being Tirm and 94mm respectively. ith a quoted weight (includg accessories) of 250kg 501b), this new diesel is only Ikg (441b) heavier than the ep engine, despite its higher iwer output, and the power/ eight ratio compares very vourably with European igines of this type.

,000 diesels a month

Kirloskar Oil Engines Ltd is .obably not too familiar a me in the European vehicle arket (although Kirloskar =mins Ltd is a joint Kirlost/. and Cummins venture tilding automotive diesels to =mins designs with an anial production potential of ier 2,500 .units). However, DEL builds some 9,000 diesel igines per month at its main ant in Pune (formerly known , Poona) in India, and the impany's range of industrial id marine diesels covers rwers from 1.9kW (2.5bhp) 277kW (372bhp).

Until the introduction of the 1.E 240, all Kirloskar engines id been built under licence orn European engine commies. When these licences exred, KOEL would make sign changes to suit local arket and manufacturing eds, but for the most part .e engine range was recognisAy European (except for the =mins engines built in a separate plant in Pune, of course).

The new 4RE 240 represents a complete departure from this established practice, therefore, and original work on the design commenced in 1971 by KOEL's own research and development department. The basic design parameters were that the new engine should replace the Jeep petrol engine without any changes in the Jeep transmission line or engine compartment structure, and also that the diesel engine should operate over a speed range close to that of the petrol engine, with almost identical torque characteristics.

Within four years of the first line being put on paper in the KOEL drawing office, some 50 engines were running experimentally in vehicles, and these test engines covered an accumulated .distance of 200,000km (125,000 miles) during this time, Road tests carried out during this period showed that at a constant 50km/h (31mph), the diesel-engined Jeep vehicle gave a fuel consumption rate of 7.5 litres/100km (37.67mpg) against the petrol-engined vehicle's average of 17.25 litres/100km (16 .4mpg)—an improvement of 130 per cent. At a constant 80km/h (50mph), the diesel vehicle returned 12.4 litres/100km (23mpg) to the petrol vehicle's 21.25 litres/ 100km (13.3mpg).

At 50km/h (31mph), the drive-by noise, test showed a level of 80dB(A) for the diesel vehicle and 75dB(A) for the petrol, while at 65km/h (40mph) both vehicles had the same exterior noise level79dB(A). Acceleration performance with the diesel engine is said to be only slightly inferior to that of the standard petrolengined vehicle.

Max power at 4,000rpm

Like the Jeep petrol engine, the Kirloskar 4RE 250 develops its maximum power at 4,000rprn. Maximum torque is 152Nm (1121bft) at 2,000rpm, compared with the 157Nm (115lbft) at 2,400rpm delivered by the Jeep petrol engine : the torque back-up of both engines is the same-26 per cent.

With an overall length from fan to flywheel of 672mm (26.45in), the 4RE 240 is only 2mm (0.08in) longer than the Jeep petrol engine, while the diesel's height of 673mm (26.85in) is actually 92mm (3.6in) less than the Jeep engine's : the Kirloskar diesel has an overall width of 540mrn (21.261n), which is 15mm (0.6in) wider than the Jeep engine. The Kirloskar diesel has wettype cylinder liners carried in a crankcase/cylinder block cast in BS Grade 15 grey iron, • the crankcase having a nominal thickness of 6mm (0.24in) and having deeply fluted sidewalls to reduce crankcase noise emission. The five-bearing crankshaft is an EN16 forging with induction-hardened crankpins and journals and aluminium-tin main and big-end bearing shells, these being supplied from another Kirloskar plant in Pune which makes Glacier bearings under licence.

The one-piece cylinder head is a grey-iron casting (phosphorous 0.15 per cent, chromium 0.5 per cent), and it incorporates Kirloskar designed pre-combustion chambers in which glow plugs are fitted for cold starting. The combustion system was developed by KOEL to give maximum turbulence with soft combustion, and at the maximum brake mean effective pressure of 841kN/sqin (1221psi) at 2,000rpm, the smoke level in the exhaust is just Bosch No 4.

The fuel-injection equipment is also Indian made, being produced in Bangalore by Motor Industries Co Ltd (MICO) under Bosch licence. The inline fuel-injection pump is gear driven from the front end of the crankshaft through an idler gear, and the mechanical governor incorporates a torque-control device and automatic advance to give an advance of about 17 degrees over the whole speed range of the engine : optimum injection timing is 27 degrees before TDC.

The MICO-Bosch fuel-injection pump has 8.5mm (0.2559in) diameter elements, and nozzle opening pressure is 10300-10800kN/sqin (15001565psi). A heat shield is provided at each injector nozzle.

Close tolerances

Pistons are of high-silicon light alloy, with particularly close tolerances to reduce piston noise under all speed and load conditions. There are four rings per piston : one chrome-plated, one taper-faced, cne stepped and one oil-control —all are above the gudgeon pin.

KOEL has made a remarkable job of not only matching the Jeep petrol engine's performance, weight and bulk, but also by any standards in developing a compact four-stroke diesel engine with above average power/weight and power/ displacement characteristics : the 4RE 240 gives 23.83kW (31,77bhp) per litre and weighs less than 4.4kg per kW (7.241b per bhp).

Although sales of the new engine are to be restricted to the Indian market this year, where there must obviously be vast sales potential for reengining petrol-engined Jeeps and similar sizes of vehicle— not to mention contractors' 'plant, etc—sales in other parts of the world are scheduled to start next year. As with most other Kirloskar products, sales in most of India's export markets are to be handled by P.M. Engines Ltd, with sales offices at 35 Piccadilly, London, W1V OM, and service headquarters at Kings Road, Newbury, Berkshire.