NEW ENGINES WITH UNUSUAL FEATURES.

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of Two New Dorman Power Units Recently Placed on the Market, One with Four Cylinders and the Other with Six.

T N the search for further effi

ciency, the power unit of _a commercial vehicle naturally comes in for a great amount of attention, and whilst it is of vital importance not to concentrate upon the engine and to neglect the remainder of the chassis, progress naturally depends to a very considerable extent upon the source of power.

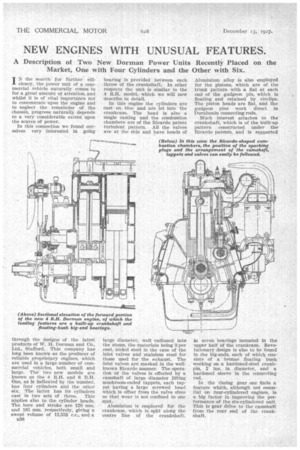

In this connection we found ourselves very interested in going through the designs of the latest products of W. II. Dorman and Co., Ltd., Stafford. This company has long been known as the producer of reliable proprietary engines, which are used in a large number of commercial vehicles, both small and large. The two new models are known as the 4 R.H. and 6 11.11. One, as is indicated by the number, has four cylinders and the other six. The latter has its cylinders cast in two sets of three. This applies also to the cylinder heads. The bore and stroke are 120 mm. and 185 mm. respectively, giving a swept volume of 12,553 c.c., and a 1338 bearing is provided between each throw of the crankshaft. In other respects the unit is similar to the 4 R.H. model, which we will now describe in detail.

In this engine the cylinders are cast en bloc and are let into the crankcase. The head is also a single casting and the combustion chambers are of the Ricardo patent turbulent pattern. All the valves are at the side and have heads of large diameter, well radiused into the stems, the materials being 3 per cent,. nickel steel in the ease of the inlet valves and stainless steel for those used for the exhaust. The inlet valves are masked in the wellknown Ricardo manner. The operation of the valves is effected by a camshaft of large diameter lifting mushroom-ended tappets, each tappet having a large screwed head which is offset from the valve stem so that wear is not confined to one spot.

Aluminium is employed for the crankcase, which is split along the centre line of the crankshaft. Aluminium alloy is also employed for the pistons, which are of the trunk pattern with a fiat at each end of the gudgeon pin, which is floating and retained by circlips. The piston heads are flat, and the gudgeon pins work direct in Duralumin connecting rods.

Much interest attaches to the crankshaft, which is of the built-up pattern _ constructed under the

Ricardo patents, and Is supported in seven bearings mounted in the upper half of the crankcase. Revolutionary design is also to be found in the big-ends, each of which; consists of a bronze floating bush • working on a hardened-steel crankpin, 2 ins, in diameter, and a hardened sleeve in the connecting rod.

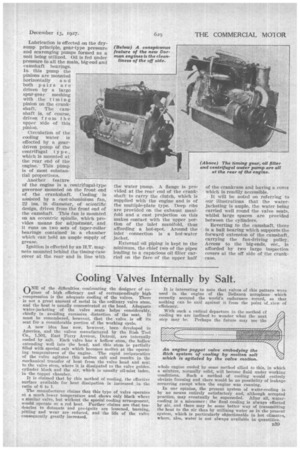

In the timing gear one finds a feature which, although not essential on four-cylindered engines, is a big factor in improving the performance of the six-cylindered unit. This is gear drive to the camshaft from the rear end of the crankshaft. Lubrication is effected on the drysump principle, gear-type pressure and scavenging pumps formed as a unit being utilized. Oil is fed under pressure to all the main, big-end and camshaft bearings.

in this pump the pinions are mounted

horizontally a n d both pairs are driven by a large spur-gear meshing with the t i In i n g pinion on the crankshaft. The camshaft is, of course, driven from the upper side of this pinion.

Circulation of the cooling water is effected by a geardriven pump of the centrifugal type, which is mounted at the rear end of the engine. This Pump is of most substantial proportions.

Another feature of the engine is a centrifugal-type governor mounted on the front end of the crankshaft. Cooling is assisted by a cast-aluminium fan, 22 ins, in diameter, of scientific design, driven from the front end of the camshaft. This fan is mounted on an eccentric spindle, which provides means for adjustment, and it runs on two sets of taper-roller bearings contained in a chamber which can hold an ample supply of grease.

Ignition is effected by an FUT. magneto mounted behind the timing-case cover at the rear and in line with the water pump. A flange is provided at the rear end of the crankshaft to carry the clutch, which is supplied with the engine and is of the multiple-plate type. Deep ribs are provided on the exhaust manifold and a east projection on this makes contact with the upper portion of the inlet manifold, thus affording a hot-spot. Around the inlet connection is a hot-water jacket.

External oil piping is kept to the minimum, the chief two of the pipes leading to a capacious oil filter carried on the face of the upper half

of the crankcase and having a cover which is readily accessible.

it will be noted on referring to our illustrations that the waterjacketing is ample, the water being carried well round the valve seats, whilst large spaces are provided between the cylinders.

Reverting to the camshaft, there is a bail bearing which supports the forward extension of the camshaft, carrying the fan-driving pulley. Access to the big-ends, etc., is afforded by two large inspection covers at the off side of the crankcase.