KELVIN HALL 8

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

REPOR1

the market requiring a ece exterior.

12.2m (40ft) long trailer on has an overall width of (8ft 2.4in) and an overall -might of 2.44m (8ft). Con?d with a Henderson roller

r rear door and a light alu71 roof, the specification orates Haacon two-speed g legs, 24 volt electrics, a le air system, load sensing ibery Owen-Rockwell runear.

PENMAN's roller-sider s said to be the first of its rith a lift-up curtain to go rvice with a spot hire rennpany. As the sole Scotlent for Lawrence David, in builds the Roller Sider t kit of parts shipped up eterborough.

exhibit built for Charthire ?s, a Scottish based rental ny, is a 7.3m (24ft) body ed on a 16-ton gvw Volvo ssis. Revised mounting arm) e nt for the 24 volt motors are now fitted inof the front bulkhead and fully protected from the weather. The top pelmet has been modified to give a tighter seal — an important aspect for insulated versions where it helps to reduce heat gain.

An example of Penman's traditional body construction is the 7.3m (24ft) refrigerated box van on show. The composite sandwich panel body is fitted with fully insulated double van doors at the rear. Their triple wiper and dust seals can easily be replaced if damaged in service. The welded alloy chequer plate floor forms a water-tight pan. A self-sufficient Petter LOC2 refrigeration unit with battery and charging system is located in the front reinforced bulkhead.

At the rear a Ross and Bonnyman tail lift with a flip-over bridging plate assists the loading of carcases onto the meat rails. The Penman-Turner DSeries air suspension unit, produced under licence from the Turner Quick-lift Corporation, Ohio, is shown here on a Ford Cargo drive axle.

As an optional extra, an antiroll bar can be included for a wide range of axles up to 10 tons rating.

The axle seat is designed to reduce working stresses common to bolt clamp assemblies while the front pivot assembly allows true axle tracking without interference of the main pivot bush.

182

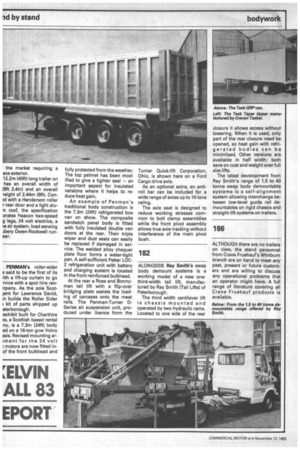

ALONGSIDE Ray Smith's swap body demount systems is a working model of a new onethird-width tail lift, manufactured by Ray Smith (Tail Lifts) of Peterborough.

The third width cantilever lift is chassis mounted and operated by two hydraulic rams. Located to one side of the rear closure it allows access without lowering. When it is used, only part of the rear closure need be opened, so heat gain with refrigerated bodies can be minimised. Other versions are available in half width; both save on cost and weight over full size lifts.

The latest development from Ray Smith's range of 1.5 to 40 tonne swap body demountable systems is a self-alignment system allowing interchange between low-level guide rail demountables on rigid chassis and straight-lift systems on trailers.

186

ALTHOUGH there are no trailers on view, the stand personnel from Crane Fruehauf's Whitburn branch are on hand to meet any past, present or future customers and are willing to discuss any operational problems that an operator might have. A full range of literature covering all Crane Fruehauf products is available.