PROFESSIONALS

Page 176

Page 177

Page 178

Page 181

If you've noticed an error in this article please click here to report it so we can fix it.

par excellence BY JOHN DARKER AMBIM

TN N the absorbing . story of road transport no chapter. " makes more fascinating reading than that of heavy

• haulage. In • -size, weight and general • awkwardness, litany of the large " indivisible loads "—as the jargon has it—present aintost insuperable difficulties. Only boldthinking. pioneering, adventurous 'types would' ' even

• contemplate moving the sort of loads _the heavy hauliers do with routine efficiency.

How necessary is it to move such huge pieces of costly manufacture across country? How "do they set about it? What is the operating routine of a heavy haulage organization? What typical problems are faced in every movement? In particular, how are the big loads moved in such a 'mountainous country as Scotland?

To find the answer to these problems I talked first to Mr, Andrew T. 'Irving, manager. of Pickfords' Northern' Operations, at Birmingham. Mr. Irving, a Scotsman with r a lifetime's experience and a European reputation, sketched in the operational background most graphically.

For the heaviest loads, be told 'me. the haulier is brought into the picture . at a very early. stage, perhaps a year or, more before the load is ready to. roll, Before the draughtsman's designs are completed the heavy plant mantifacturer IS likely to have discusSeci With the haulier the practicability and the likely cost of moving the equipment in question. The haulier will be familiar with main-road obstacles, bridge strengths and heights, and the like, but heavy movements along remote narrow roads in the-Highlands of Scotland, for example, will certainly necessitate a detailed route survey, and access to the final destination can, and frequently does, present major difficulties. And, of course, the heavy haulier's job does not normally end until the equipment has been erected on site.

Heavy plant manufacturers do not lightly send equipment by road. If rail, sea or canal can be used, road movement is not considered. But loading gauges on rail and canal are limited; ports are not always conveniently placed, and even when they are their dockside facilities may not include suitable heavy lifting facilities.

The overriding justification for heavy plant movements by road is the contribution that such movements make to the British economy. It is for this reason that the authorities, the Ministry of Transport in Scotland, the. Scottish Home Department) highway and bridge authorities, post office telephone service and municipal engineers and surveyors—co-operate unstintingly. " Without this co-operation Mr. Irving stressed, "we simply couldn't do the job ". " I am glad to pay tribute, here, io the many

" backroom boys" of the various authorities mentioned who, at the planning stage as well as during the actual movement, give of their time and experience without thought for personal convenience.

Everything Mr. Irving told me illustrated the professional approach of Pickfords to the art (or science) of heavy haulage.

There are no set rules or text books to guide the novice; experience is the only guide. I was not surprised to learn that all the crews of the heavy haulage outfits undergo a long and arduous apprenticeship; and, of course, the managerial force combines concentrated commercial training with extensive field experience. Throughout, older, trained men look after the youngsters for whom, said Mr. Irving, " there are terrific opportunities, for those prepared to work like hell."

The Nant Project Mr. A. C. MacKinlay, Pickford's Scottish manager, gave me a detailed insight into the hazards successfully overcome in moving plant to the Nant Generating Station, in Argyllshire, which was recently opened by Her Majesty The Queen.

The delivery of a stator weighing 40 tons, a rotor, 35 tons, and a transformer of 60 tons net weight, along narrow, twisting, steep and—by modern standards—quite primitive access roads, presented particularly difficult problems; and, for good measure, the equipment had to pass along a 16 ft.-diameter tunnel, a quarter, of a mile long, cut through the heart of the mountain to the generating chamber.

Mitch heavier loads, indeed up to 240 tons single-piece dead weight, have been delivered to power stations elsewhere by Pickfords, but the weight and size of the plant for the Nant generating station; in relation to certain access roads, presented exceptionally formidable hazards. That part of the route branching from the A85 just south of Taynuilt by a class C road is normally restricted to a gross weight of 12 tons. It is a formidable road, even for a car, twisting uphill and down, through glens and villages, and only. 8 ft. wide in places, with heavily cambered curves.

Following a detailed route survey and consultation with highway and bridge authorities and the consultants of the North of Scotland Hydro-electric Board, arrangements were made for the shoring and overlaying of certain

?6 weak bridges responsible for the restriction on the section outlined in the accompanying sketch. The road surfaces over bridges and culverts were reinforced to ensure safety with the particular axle and wheel loadings of the trailer to be used, a 32-wheeled, solid-tyred Special Types trailer which gave a gross weight of trailer and load, with the heaviest piece (the transformer) of 100 tons, plus the weight of the two tractors, approximately 22 tons each.

The particular trailer to be used was dictated by the route, it being necessary to consider all the factors of total gross weight, individual axle and wheel loadings, ability to negotiate the acute bends en route, and so on. Other trailers on pneumatic tyres and quite capable of dealing with loads of this description and weight under normal conditions were ruled out because of their greater size and lesser manceuvrability and/or by the higher gross weight involved.

It was then discovered that the GPO transatlantic cables ran alongside the edge of the road to Kfichrenan and crossed it at about a dozen places over a distance of six miles. Consultation with the West of Scotland telephone manager's office established that the cable consisted of one original armoured cable and a recent plastic. covered non-armoured one liable to break under the weight of, the transporter. Had this occurred, a loss of revenue approaching £10 per minute could have been involved!

To overcome this particular risk, arrangements were . made for the GPO to have an engineer in attendance whilst the loads were in transit to locate and indicate vulnerable points, at which Pickfords undertook to overlay the road surface with substantial steel plates to provide better weight distribution over the vulnerable spots.

At planned times the loads were taken along the route branching from A85 under police escort, and some amusement was caused at the restrictive " 12 tons" road sign, in relation. to the gross train weights of up to 140 tons, as the tractors pulled hard up a I in 10 gradient with a vicious hairpin bend 100 yd. ahead.

The last few miles were not free from incident. About five gallons of diesel oil were lost from the offside of one of the tractor's tanks as it heeled over on a bend, indicative of the conditions encountered. Because the width over the trailer axles was 9 ft. and the road narrowed to 8 ft. in places, at times some of the wheels ploughed through the roadside peat and heather. • Constant rear steering of the trailer was necessary, with crawl speeds over long stretches requiring the closest co-operation between driver and .steersman. Any slight error could readily have resulted in the trailer leaving the road, and presenting a formidable, and costly, recovery task.

The sponge-like give in the road surface on the last few miles to Nant was noteworthy, emphasizing the need for the multi-wheeled trailer used and the necessity to keep moving, however slowly. •

Stops were made at selected points to enable other traffic to pass, and to enable the protective steel plates laid over. vulnerable places to be lifted and relaid in other sections. A separate service vehicle and crew were provided for this purpose.

With care, patience, perseverance and much hard work on the part of the crews, this terminal section of tortuous road was negotiated with each load. It is hardly surprising that the combination of road-plating, traffic stops and precise rear-end steering called for did not make for speedy progress: in fact, nearly 11 hours were spent in moving about nine miles.And the reception party? Alas, nothing more than sheep, grazing round the site huts!

A little more patience, skill and experience enabled each .Continued on page 179 load to be placed under the crane hook in the generating hall and, upon the exit of the vehicles, the tunnel returned to its deathly cold and somewhat awesome appearance. Another recent rnovement in which Pickfords can take justifiable pride concerned the transport of a huge 181-ton , storage shell from the Renfrew works of the makers, Babcock and Wilcox (Operations) Ltd., to the nuclear power station at Wylfa, in Anglesey.

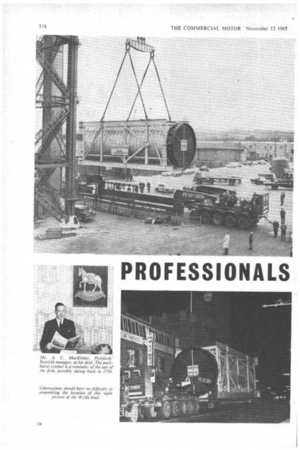

By arrangement with Babcock and Wilcox, and Pickfords, I was able to watch the loading of this monster object. 521 ft. long, 18 ft. wide and nearly 24 ft. high, and the largest load ever carried on British roads, having regard to all dimensions plus weight.

The loading was preceded by the-sideways movement of the container, and its lowering from a height of 6 ft., for some yards across the floor of the assembly shop. This operation—almost akin to launching a ship sideways— was accomplished using powerful hydraulic jacks and stout baulks of timber.

The Crane trailer, with normally a 55-ft. well, had been specially strengthened and lengthened to accommodate the load. A 19 ft. 6 in, girder section was bolted in the trailer centre section for this purpose—in itself a considerable engineering feat. The designers and stressrnen concerned may be rightly proud that their strength calculations proved equal to all demands the journey imposed.

In the loading position at last, the trailer was manceuvred into place and the storage container was slowly lowered by four 100-ton jacks on to the trailer. It was quite an experience to watch the designed "bow" of the main girders (some 7 in.) flatten as the load descended.

It was a great moment for the Babcock and Wilcox engineers who had lived with the storage container for over a year, and for the Pickfords team who had planned the movement for almost as long, as the Seammell Super Constructor vehicles, powered by 195 h.p. Albion diesel engines, inched thrward.ffirough the factory doors, pulling and pushing the 125 ft.-long outfit.

To protect the yard surface and rail tracks outside, large steel plates:71 in. thick had been laid. There was no more than 2 in. clearance as the container passed through the factory doors precisely on time (5 p.m. on a Sunday). The steel plates surmOunted, the outfit turned left add slowly proceeded down the works drive, squeezing narrowly past gate-houses and other buildings and necessitating the•

swinging aside of lighting standard arms. ,

At the foot of the drive, to enable a sharp right-hand bend to be negotiated, the leading tractor was uncoupled. so that both prime movers could push thetrailer. round the corner. The tight radius called for the use -of planks and steel plates to protect a raised pavement from the weight of the trailer wheels. Promptly—in fact at 5.55 p.m. against a planned time of 6 p.m.—the load moved slowly across a level crossing outide the works, one gate of which had been removed to provide clearance.

After a break for ,crew refreshments, the massive load continued its ponderous progress, under police eseort and. observed by many interested spectators, some of whom enlivened the proceedings with ribald comments! In Glebe Street a traffic bollard was cleared by the thickness of a tram ticket, to the relief of all concerned.

Space forbids a detailed account of the load's progress to Glasgow docks, but it involved the lifting of telephone lines and the temporary disconnection of trolley power lines. John Harrison, Alex MacKinIay's assistant, walked backwards down the length of Glebe Street acting as " link man" to the four men on top of the load who were dealing with lighting wires. He tells me he had "very sore legs " afterwards!

Early on the Wednesday morning the loaded trailer arrived at Stobcross Quay, Glasgow, and by 2 p.m. the container and trailer had been separately stowed on the MV Leven Fisher ", bound for Holyhead.

Other adventures iniAnglesey, no less difficult, were surmounted successfully, and final delivery to the Wylfa site was made in good order.

To foreman A. Vincent and his five-man Birmingham crew, and to the Pickfords managers who planned and executed this remarkable movement, this was a truly professional job.