For Frequent Stops and Tight Turn

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

'HE KARRIER BANTAM

A Vehicle Built Specifically for Local 'Work Reveals SilltPtiCity and Stardiness in Design, Combined with Exceptional Manoeuvrability on the Road and Good Braking p°PULAR with municipalities for use as a large-capacity refuse collector, the Karrier Bantam is also favoured by many other operators as a low-loading goods vehicle. Its ability to turn in a circle of slightly more than 33 ft. on both locks makes it specially suitable for work in urban areas.

• The chassis is notable for its simplicity in design and for the accessibility of components. Located forward of the front axle, the engine and its auxiliaries are readily reached after removing the bonnet covers from inside the cab.

Of straightforward design, the four-cylindered engine develops 40 b.h.p. at 3,100 r.p.m. Crankcase and cylinder block form a single casting, renewable liners being fitted to ease overhauls. The head, which is also a single casting, incorporates high-efficiency combustion chambers.

The valves, made from silicon steel, have 1 enewable guides, and the exhaust-valve seats are replaceable. The valves are operated through barrel-pattern adjustable tappets from a three-bearing camshaft and are controlled by dual springs.

Light cast-iron pistons are retained on the I-section connecting rods by large-diameter gudgeon pins. Steelbacked white-metal-lined bearings are used for the connecting rod big ends and main bearings, the crankshaft being retained in position on three journals A duplex roller chain connects the crankshaft to the camshaft, a spiral gear from the camshaft being used to drive the oil pump and distributor.

Fan, water impeller and 154 dynamo are driven by an adjustable V-belt and pulley from the front of the crankshaft. The gear-pattern lubrication pump, with the suction side well protected by a filter, supplies oil under pressure to all camshaft and crankshaft bearings and a jet feed to the cylinder bores. Oil draining back to the sump passes through a fine gauze filter which covers the top of the crankcase base.

Other features of the engine include hot-spot exhaust manifolding, a Solex governed carburetter and high-voltage coil with wide-gap sparking plugs. To assist in reducing cylinder wear and to combine maximum efficiency with economy, a by-pass thermostat is fitted to control the temperature of the engine cooling water.

Engine, clutch and gearbox are carried in the frame on three Silentbloc rubber mountings. The clutch, which is fitted with taper-roller bearings and enclosed in a pressed-steel casing.

Made from an. I-section sleet stamping, the front-axle beam is fitted with heavy-duty stub axles which support the road-wheel hubs on taper-roller bearings. The Libular tierod has Thompson< self-adjusting ends, and all steeringconnection levers are made from heat-treated steel forging&

Consistent Braking

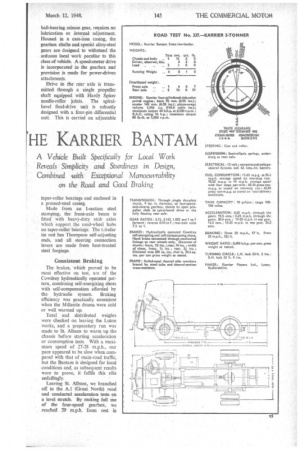

The brakes, which proved to be most effective on test, are of the Cowdrey hydraulically operated pattern, combining self-energizing shoes with sell-compensation afforded by the hydraulic system.. Braking efficiency was practically consistent when the Millenite drums were cold or well warmed up Total and. distributed weights were checked on leaving the Luton works, and. a preparatory run was made to St. Albans to warm up the chassis before starting acceleration or consumption tests. With a. maxinunn speed of 27-28 m.p.h., our pace appeared to he slaw when cornpared with that of main-road traffic, but the Bantam is designed for local conditions and, as subsequent results were to prove, it fulfils this rile Leaving: St. Albans, we branched off to the Ai (Great Nortb). road and conducted acceleration tests on a level stretch. lily making hell use of the four-speed gearbox, we reached 20 m.p.h. from rest in 19.5 secs., 25 mph. in 30.6-secs., and the governed speed of 28 m.p.h. in 42.7 secs. Top-gear acceleration from 10 m.p.h. resulted in a smooth take-up in the transmission, 20 m.p.h. being attained in 14.5 secs., 25 m.p.h. in 24.3 secs. and 28 m.p.h. in 31.5 secs.

1 changed places with the works driver for the braking tests. Frequently stopping and dismounting from the cab to take measurements, 1 much appreciated the easy access to the driving seat.

On the. first attempt to change gear, I brought the gear lever back to the second-speed position and jammed my elbow into the bulkhead panel, a procedure which I managed to avoid in subsequent changes.

High Brake Efficiency An average taken of the stopping distances from 20 m.p.h. showed that the Bantam could be brought to rest in 17 ft., which corresponds to 79 per cent. efficiency. From 25 m.p.h. we came to rest in 33i ft., which is equivalent • to slightly over 62 per cent. Consistent results were obtained, although the brakes were showing visible signs of warming up.

From this stage we travelled on towards Stevenage for the consumption tests, which included climbing Welwyn Hill. A small fuel tank was brought into circuit and was filled before the test was started. A quantity equal to that used was measured in at the end of the test in each direction. The first test made withont stop produced a consumption rate of 15.36 m.p.g. and on the return journey 15.90 m.p.g. was recorded, the average of the two being 15.63 m.p.g. Average speed throughout the two runs was 24.4 m.p.h.

The second test, representative of 131 local delivery work, with four stops per mile, raised the consumption to 10.52 mpg. and, deducting the interval of 15 secs. spent at each point, the average running speed was 14 m.p.h. This test was made more severe by stopping and starting the engine at each point.

As these were the conditions under which the Bantam would be most likely to operate, the running temperatures were taken at the end of the stop-start test. With an atmospheric temperature of 64 degrees, F., the temperature readings taken throughout the chassis showed a radiator reading of 187 degrees F., engine oil 168 degrees F., gearbox , 122 degrees F., and back axle 140 degrees F. Considering the . severity of the test, these temperatures show that the units are adequately cooled for local delivery service.

We then continued our course towards Wiley Hill. Starting from rest at the foot of the hill, the Bantam proved to be well geared for the occasion, and after climbing the lesser gradient in second gear surmounted the steeper portion in .

low gear at maximum engine revolutions. Radiator-water temperature showed a rise of 14 degrees F. during the test. Returning to the 1-in-9 gradient, we made a stop-start test without difficulty and found the hand brake to be sufficiently powerful to hold the vehicle,

Small Turning Circle

The turning circle was checked at the top of the hill, 33 ft. 2 ins. being recorded for the left lock and 33 ft. 8 ins, for the right lock. These figures appear to be outside the limits specified for the vehicle, and I was assured that the stops could be adjusted to produce a tighter turn.

The Bantam is well suited to local cpllection and delivery. The economical performance on straight running proves that it can well compare with vehicles of similar capacity, and the low loading height is of great advantage where loads have to be manhandled.