Hobbs Transmissior Suits Ambulance

Page 38

Page 39

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

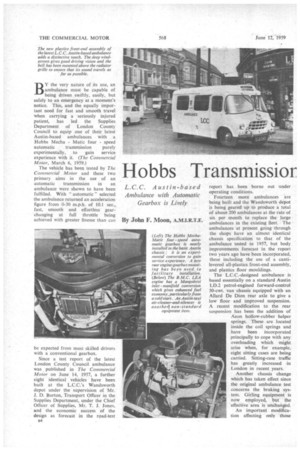

L.C.C. Austin-based Ambulance with Automatic Gearbox is Lively

By John F. Moon, A.M.I.R.T.E. BY the very nature of its use, an ambulance must be capable of being driven swiftly, easily, but safely to an emergency at a moment's notice. This, and the equally important need for fast and smooth travel when carrying a seriously injured patient, has led the Supplies Department of London County

Council to equip one of their latest Austin-based ambulances with a Hobbs Mecha Matic four speed

automatic transmission purely experimentally, to gain service. experience with it. (The Commercial Motor, March 6, 1959.) The vehicle has been tested by The Commercial Motor and these two

primary aims in the use of an automatic transmission in an ambulance were shown to have been fulfilled. With " automatic" selected the ambulance returned an acceleration figure from 0-30 m.p.h. of 10.1 sec., fast, smooth and effortless gear changing at full throttle being achieved with greater finesse than can be expected from most skilled drivers with a conventional gearbox.

Since a test report of the latest London County Council ambulance was published in The Commercial Motor on June 14, 1957, a further eight identical vehicles have been built at the L.C.C.'s Wandsworth depot under the supervision of Mr. J. D. Burton, Transport Officer in the Supplies Department, under the Chief Officer of Supplies, Mr. T. J. Jones, and the economic success of the design as forecast in the road-test

B4 report has been borne out under operating conditions.

Fourteen more ambulances are being built and the Wandsworth depot is being geared up to produce a total of about-200 ambulances at the rate of six per month to replace the large ambulances in the existing fleet. The ambulances at present going through the shops have an almost identical chassis specification to that of the ambulance tested in 1957, but body improvements forecast in the report two years ago have been incorporated, these including the use of a cantilevered all-plastics front-end assembly, and plastics floor mouldings.

The L.C.C.-designed ambulance is based essentially on a standard Austin LD.2 petrol-engined forward-control 30-cwt. van• chassis equipped with an Allard De Dion rear axle to give a low floor and improved suspension. A recent modification to the rear suspension has been the addition of Aeon hollow-rubber helper springs. These are located inside the coil springs and have been incorporated principally to cope with any overloading which might arise when, for example, eight sitting cases are being carried. Sitting-case traffic has greatly increased in London in recent years.

Another chassis change which has taken effect since the original ambulance test concerns the braking system. Girling equipment is now employed, bin the effective, area is unchanged.

An important modification affecting only those

chassis supplied to the L.C.C. is the use of a Marigoletsi inlet manifold on the B.M.C. LEA four-cylindered petrol engine. Such manifold conversions, produced by the G.M. Carburetter Co., Ltd., Malt Street,Knutsford, Cheshire, have successfully been applied for several years to private cars, but this is the first instance of their application in appreciable numbers to commercial-vehicle chassis.

The effectiveness of the manifold has been proved by tests carried out by the L.C.C. at the Wandsworth depot during the cold weather at the beginning of this year. Circuits, each of two miles, were made at regular intervals from 8 a.m. onwards, the vehicle having been standing in the depot overnight. The first run showed an improvement of more than 20 per cent, when compared with that obtained from an unmodified engine under the same conditions, whilst the overall fuel saving under directly comparable conditions ranged between 5 and 10 per cent.

As much of the running performed by an ambulance in London consists or short-distance work, the improvement in cold running is of great importance and it is primarily for this reason that the ivlangoletsi manifold has been adopted.

The Hobbs Mecha-Matic gearbox which had been experimentally fitted by Hobbs Transrnission,-Ltd., to the ambulance tested is similar to that which has been successfully applied to several Austin taxis. The gearbox is available with two sets of ratios; these are 3.42, 2.02, 1.39 and Ito 1 forward, with a reverse ratio of 5.2 to 1, or, as tested, 4.84, 2.58, 1.525 and 1 to 1 forward, reverse being 6.31 to I. Slight modifications to the standard Hobbs specification have been made to suit the L.C.C.

It was possible to mount the Hobbs box in the Austin chassis without the need for a new propeller shaft, but the rear engine mounting had to be modified. In the standard chassis the rear of the engine-gearbox unit is carried on rubber mountings located on each side of the clutch housing, whereas for the Hobbs application a mounting bracket was attached to a new chassis cross-member, extensions of which carry the forward Metacone body mountings. To this bracket were bolted two rubber sandwich mountings, situated close together in the form of a V to make in effect a single-. point mounting.

The principal bodywork changes since • the original, ambulance was tested in .1957 were outlined in • The Commercial Motor on March 6.. They consist of an all-plastics front-end assembly cantilevered from the . main body shell,. and free to move slightly about the chaisis4nou-nted cab 'floor,

. . . _

and an , all-plastiCs floor . cotriprisitig three mouldings bolted together. These . floor mouldings Contain 50 per Cent. powdered slate in -the gel 'coat only, which has been added to give increased wear resistance and provide colouring •

for the floor.

• The floor has been made in three pieces, partly to facilitate production, but principally because it would have been impossible to pass a one-piece floor in through the rear doors. The floor assembly is in no way stressed and is added after the sides and roof have been assembled on the chassis. It is secured to the sides by rubber glazing strip and rests on longitudinal rubber strips secured to the top of the chassis frame.

Plastics construction throughout has

appreciably reduced the amount of engine and transmission noise penetrating the body. The plastics floor, in particular, keeps out .a high proportion of the normal road and exhaust noises. The exhaust system itself has been improved compared with that fitted to the original ambulance, a Princess car silencer being installed.

As supplied for test, the ambulance, complete with four stretcher beds, had a kerb weight of 1 ton 171 cwt. Weights totalling 31 cwt. had been placed on the beds to represent the weight of two patients and medical equipment. Complete with myself, staff photographer and Mr. Burton aboard, the ambulance was tested at a gross weight Of 2 tons 6 cwt.

As in the 1957 test, the ambulance was first taken through the south London suburbs to Succombs Hill, near. Caterham. This notorious incline is half a mile long with an average gradient of 1 in 9 and sections of 1 in 5 and i in 4.

Automatic Changes Ambient temperature was 48°F. and before making the climb the water temperature was ascertained as 159°F. The ascent lasted 1 minute 40 seconds with the gearbox in " automatic " the whole time and most of the climb was made in second ratio, although the box changed up into third for a few seconds between the two steepest parts of the hill and into bottom just above the 1 in 4+ section.

This change from second to bottom seemed to be unduly delayed. Had the chassis been fitted with a normal manually operated gearbox, a competent driver would have changed into bottom gear before reaching this part of the gradient. The changing point has been kept low deliberately, though, to avoid numerous down-changes in traffic. The climb caused the water temperature to rise by only 10°F. The total time of the ascent was 25 seconds longer than that recorded with the 1957 version with a manual gearbox.

Slower But Surer So far as hill-climbing performance is concerned, the Hobbs transmission reduces speed, but automaticgear changes ensure that a non-stop climb is made, whereas on a gradient of this nature it would be easy for an inexperienced driver to miss a change with a constant-mesh type of transmission and bring the vehicle to a halt.

For the descent of the hill, I decided to try out the manual overriding control claimed to be a feature of the transmission, but, because of the operating pressure setting of the box, it was not possible to obtain engine braking in the normal manner. The pressure .setting has been reduced

specially for the arnbUlance application to ensure very smooth downward changes in the course of normal driving, this having been deemed more important than the provision of engine braking on steep gradients.

In effect, therefore, when descending Succombs Hill with the, manual control set to "second," as soon as the speed rose above about 10 m.p.h. with the engine idling, the gearbox automatically changed into neutral. A way out of this difficulty was eventually found.

The technique is to keep the throttle slightly open, but' This is a most unnatural way of descending a hill. I decided, therefore, that it was better

to ignore the possibility of obtaining engine braking and to go down the gradient with the foot brake applied. A brake-fade test was dot carried out, but as the facing area on the latest ambulance is the Sarne as that of the earlier version, fade. performance .should be similar. In 1957, no fade at

. all occurred when descending Succombs Hill.

The ambulance was returned to and stopped on the 1 in 4+ gradient where the hand brake 'held it after. being helped on with the foot brake. Successful restarts—most of • them

• smooth—were made from this point, but occasionally slight judder was noticed as full torque was passed through the transmission.

Quick Changes

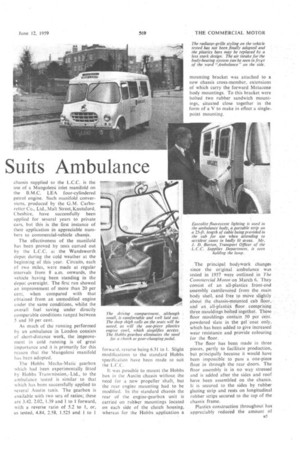

Acceleration figures obtained with " automatic " engaged from a standstill up to 40 m.p.h. were most gratifying. Although the 0-20 m.p.h. figure . was 0.6 sec. slower than that given by the original ambulance in 1957, the results up to 30 m.p.h. were 0.5 sec. better and to 40 m.p.h. 1 sec. better. These improvements have been brought about by the rapid continuoustorque changes made by the Hobbs box.

It was, of course, impossible to carry out direct-drive acceleration tests between 10 m.p.h. and 40 m.p.h., because the automatic transmission will not stay in top gear below about 12 m.p.h. and even at that speed when full throttle is applied third gear is automatically re-engaged.

For the standing-start acceleration tests full throttle was used, incorporating the " kick-down " position, this giving changing-up speeds of 18 m.p.h. between second and third and 35 m.p.h. between third and fourth. Upward changes between these ratios at normal throttle openings were in the region of 12 m.p.h. and 19. m.p.h. respectively, with an initial change from bottom to second at about 5 m.p.h. Downward changes under normal conditions occurred at 12 m.p.h. from top to third, 8 m.p.h. from third to second and below 5 m.p.h. from . second to first.

Three Fuel Tests

As in 1957, three sets of fuel figures were taken. The first was along a fourmile circuit of reasonably traffic-free road in the Wimbledon area. The course was completed at an average speed of 28.5 m.p.h. and produced a " country " consumption figure of 23.5 m.p.g., or 1.1 rn.p.g. better than was obtained in 1957 over the same course at the same speed.

Next a " town "test was conducted between Wimbledon and Wandsworth, passing through Tooting, Balham and Clapham. The run was 10 miles long, during the course of which 13 traffic stops were made, two of three minutes each. The distance was covered at ad average speed of 17.7 m.p.h., the consumption rate being 21 m.p.g. as shown by the Petrometa. Again this was an improvement on the figure obtained in 1957, when 20 m.p.g. was recorded over a similar course.

A high-speed five-Mile run was then made along the Kingston by-pass, with 'three stops at traffic lights. The average speed was 38 m.p.h. and the indicated consumption rate was 18 m.p.g., which in this case was 2.9 m.p.g. heavier than was obtained in 1957.

This decrease in economy occurred partly because the 1957 run was accomplished non-stop, whereas on this occasion full acceleration was used when pulling away from each of the trafficlight halts. The vehicle was driven with maximum acceleration and the highest possible speed the whole time.

Fuel figures had also been taken on the journey out to Succombs Hill and back, both legs of the journey being completed at an average speed of 25 m.p.h. The climb out to Caterham produced a rate of 18.8 m.p.g., the return run giving 22.4 m.p.g.—an overall figure of 20.4 m.p.g.

treater Economy

Except on the high-speed run, the latest ambulance was more economical than the earlier version, although it is impossible to divide the credit for this improvement accurately between the MangoIetsi manifold and the Hobbs transmission. Figures show, however, that, assuming the Mangoletsi manifold to give a 5 per cent. improvement in fuel economy, the Hobbs all-mechanical transmission does not detract from this gain in normal town and country service.

Braking tests produced greater stopping distances than were obtained in 1957 on the chassis. with Lockheed brakes, all other conditions being equal. The hand-brake efficiency, however, was higher than with the earlier model, an average figure of 33.5 per cent. being obtained from 20 m.p.h.

The performance of the Hobbs gearbox generally was satisfactory. Both upward and downward changes were commendably smooth, and " epicyclic whine" was almost undetectable. The continuous-torque characteristics help to ensure smoothness without the slight fall-off in speed which invariably occurs when making changes with a cOnventional transmission.

There were occasional signs of judder in second ratio when. accelerating, and at times the initial take-up from stand still was a little harsh.. This could be caused by the rear mountings of the lusty -B.M.C. LEA engine.'

The torqUe output is satisfactorily absorbed by the standard wide-set rear Mountings, but can cause an excessive amount of engine-gearbox movement with the close-set rear Mountings of the Hobbs application: A rubber snubber to restrict engine movement is possibly to be applied by the L:C.C. engineers, in which case any transmitted.roughness should be removed.

Easy to Drive

.

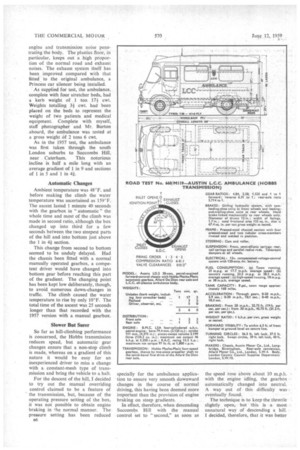

This, ambulance is exceptionally pleasant to -handle and the deep, wide two-piece curved windscreen enables it to be taken through heavy traffic with confidence. Because of the need to provide the maximum body space in the shortest possible overall length, the cab appears a little cramped, but there is more room for the driver than would at first be assumed.

Because of the forward seat position, however, entering and leaving the cab are not as easy as with a vehicle of conventional design. The seats are most comfortable, the cushions incorporating deep rubber-filled thighsupport rolls which do much to reduce leg fatigue.

General riding characteristics are first-rate, the De Dion rear-end successfully reducing roll to a minimum. The non-standard over-length front springs are matched in characteristics to the, rear coil springs, so that there is none of the pitching often found in a short-wheelbase vehicle, and the damping successfully 'cuts out excessive vertical movement over harsh road surfaces.

Fluorescent Lighting

A detail body point worth noting is the use of Eascolite transistorized fluorescent lighting in the front and rear of the body (the rear body light illuminating also the rear number plate) and for the " Ambulance " sign. A portable strip of fluorescent lighting with a 25-ft. length of cable is installed in the cab. It is for use when attending to accident cases in badly lit areas, but also has been useful for an attendant to guide the driver in thick fog.

Maintenance will be almost identical to that of the standard Austin chassis, details of which may be obtained from the road-test report of the Morris 1-ton van published on May 4, 1956. Engine accessibility has,' however, been improved by a one-piece plastics cowl, as opposed to the two-piece metal assembly used on the standard chassis. The choke and starter controls do not have to be disconnected when removing the engine cowling, being mounted on the dash panel. .