Facilitating Gear Engagement

Page 68

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Patent Specifications that Have Recently Been Published

rrHE necessity of synchronizing the speeds of two gearwheels before attempting to engage them is now gener ally admitted, and patent No. 402,221 by the Austin Motor. Co., Ltd., Birminghant, Shows a simple and effective method of achieving this.

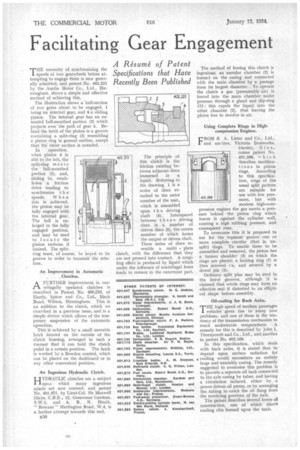

The illustration shows a half-section of two gears about to be engaged, 1 being an internal gear, and 4 a sliding pinion. The internal gear has an extended 'bell-mouthed portion (2) which projects over the path of gear 4. Behind the teeth of the pinion is a groove containing a split-ring (3) resembling a piston ring in general outline, except that the outer surface is rounded.

In operation, when pinion 4 is slid to the left, the split-ring m eets the bell-mouthed portion (2), and, sliding in, establishes a friction drive tending to synchronize t h e speeds. When this is achieved, the pinion may be fully engaged with the internal gear. The bell is enlarged in the fully engaged position, and may be used to locate the pinion endwise if desired. The split ring must, of course, be keyed to its groove in order to transmit the rotation.

An Improvement in Automatic Clutches.

AFURTHER improvement in centrifugally operated clutches is described in Patent No. 400,210, of Hardy, Spicer and Co., Ltd., Birch Road, Witton, Birmingham. This is an addition to the clutch, which we described in a previous issue, and is a simple device which allows of the temporary suspension of the automatic operation.

This is achieved by a small movable latch located on the outside of the clutch housing, arranged in such a manner that it can hold the clutch pedal in a certain position. The latch is worked by a Bowden control, which can be placed on the dashboard or in any other convenient position.

An Ingenious Hydraulic Clutch.

HYDRAULIC clutches are a subject upoa which many ingenious minds are now centred, and patent No. 401,371, by Lieut-Col. Sir Maxwell Hicks, C.I3.E., 12, Grosvenor Gardens,. S.W.1; and A. R. N. Heath, "

Rowans" Hartingtrin Road, W.4, is a further attempt towards this end. 401,371 The principle of this clutch is the friction existing between adjacent discs immersed in a liquid. Referring to the drawing, 1 is a series of discs attached to the outer member of the unit, which is assembled upon t h e driving shaft (4). Interspaced between t h ese driving discs is a number of driven discs (5), the centre member of which forms the output or driven shaft. These series of discs resemble a multi plate clutch, with the difference that they are not pressed into contact. A coupling effect is produced by liquid which under the influence of centrifugal force tends to remain in the outermost part. The method of freeing this clutch is ingenious an annular chamber (2) is formed on the casing and connected with the main chamber by a passage from its largest diameter. . To operate the clutch a gas (presumably air) is forced into the main chamber under pressure through a gland and slip-ring (3) ; this expels the liquid into the other chamber (2), thus leaving the plates free to revolve in air.

Using Complete Rings in Highcompression Engines.

FROM R A. Lister and Co., Ltd., and nor ther, Victoria Ironworks, Dursley, G 1 o s., comes patent No.

401,268, hic h describes modifications in piston rings. According to this specifica tion, rings of the usual split pattern are suitable for • use with low pressures, but with modern high-compression engines the gas exerts a pressure behind the piston ring which forces it against the cylinder wall, causing a high rubbing pressure, and consequent .roar.

To overcome this it is proposed to use for the _ topmost groove one or more complete circular (that is, unsplit) rings. To enable these to be assembled and removed, the piston has a turned shoulder (3) on which the rings are placed; a locking ring (I) is then screwed rn, and secured by a dowel pin (2).

Ordinary split pins may be used in the lower grooves, although it is claimed that whole rings may form an effective seal if distorted to an elliptical shape before' assembly.

Oil-cooling for Back Axles.

rr HE high speed of modern passenger vehicles gives rise to many new problems, and one of these is the tendency of the transmission mechanism to reach undesirable temperattires. .A remedy for this is described by John I. Thornycroft and Co., Ltd., and another in patent No. 402,169.

In this specification, which deals with back axles, it is stated that to depend upon surface radiation for * cooling would necessitate an unduly large and unwieldy casing. The remedy suggested to overcome this problem is to provide a separate oil tank connected to the axle casing by tubes, and having a circulation induced, either by a power-driven oil pump, or by arranging the tubing to catch the oil flung from the revolving portions of the axle.

The patent describes several forms of construction a ., one of which show cooling ribs formed upon the tank.