HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best out of a Vehicle, to Secure Reliability and to Avoid Trouble.

664.—An Improvement to the Clutch Shaft of the 4-5-ton. Maudslay.

Connecting the drive from the clutch to the gearbox of the 4-5-ton Maudslay is a special coupling having four studs. These sometimes break off, in which ease a day's work may be lost, because to renew them it is necessary to take down the short driving shaft and part of the clutch, so that the broken studs can be removed and replaced by new ones.

The task can be greatly facilitated, and the time wasted much reduced, by drilling out the four stud holes to in, and replacing the studs by 2i-in. by fin, steel bolts. Now, if these bolts break, all that is necessary is to refit new bolts, which can be effected in a few minutes, providing that spares be carried.

665.—Dropping the Sump on the 3-4-ton A.E.C.

Engine.

Some users who have not had a long experience with Ty-for-engine() 3-4-ton A.E.C. chassis have experienced difficulty in dropping the lower half of the crankcase. This can quite easily be carried out if the following procedure be adopted.

The brake rod should first be disconnected from the near side and swung round to the off side; next, the four engine holding-clown bolts must be removed, and a jack can then he placed under the flywheel and screwed up until the engine is raised at the rear 'end about 2 ins. It is not necessary to disconnect any joints before carrying out this operation, and it will then be found that the part in question can be removed quite easily.

666.—Obviating Slip of the Magneto Coupling on the 15-ter Fiat.

A fault sometimes found on the 15-ter Fiat is a gradual slipping of the magneto coupling, which is often. not suspected until the engine actually fails, although it. begins to be inefficient some time before this happens. One serious effect of the slipping and the resultant retardation of the ignition is that the exhaust valves are apt to be burnt.

Many experiments have been made to cure the trouble, Such as fitting paper washers between the flanges, Nit c46

the actual fault lies with the bolts which united the cdupling. One flange has a dovetailed groove which accommodates the V-shaped bolt heads; the other, that on the magneto, simply has three holes for the bolts. These bolts are tightened on the inside of the groove provided, but sufficient clearance is not always left, so that the heads project from the groove and tighten against the wrong flange. If a little of the metal be filed away from beneath the head of each bolt, the amount being sufficient to afford adequate clearance, the trouble will be cured.

667.—Repairing Cracked Valve-cap Bridges on • the Tylor Engine.

On numerous occasions we have published details of methods by which eracked valve-cap bridges on the Tylor engine can be repaired. • A new one which appears to have given every satisfaction is to insert a piece, of copper, about I in. thick and 1 in. long, into the crack of the cylinder, cutting a double dovetail, and suitably shaping the copper. .After insertion it can be filed to give a smooth surface and to fit the valve caps.

The chief point in this repair is that the copper expands more rapidly and to a greater extent than the cast-iron cylinders, and thereby a perfect joint is ensured.

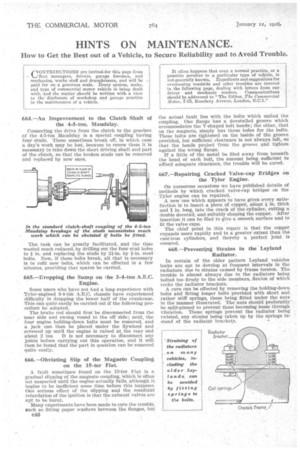

668.—Preventing Strains in the Leyland Radiator.

In certain of the older pattern Leyland vehicles leaks are apt to develop at frequent intervals in the radiators, due to strains caused by frame torsion. The trouble is almost always clue to the radiators being bolted too firmly to the side members, flexion of which rocks the radiator brackets.

A cure can be effected by removing the holding-down bolts and fitting longer bolts provided with short and rather stiff springs, these being fitted under the nuts in the manner illustrated. The nuts should preferably be split-pinned to prevent them becoming loose through vibration. These springs prevent the radiator being twisted, any strains being taken up by the springs instead of the radiator brackets.