A NE\ VPLEMENT for the MECHANIZED LAND ARMY

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

RECLAMATION of land for home food production has presented many problems. It is no exaggeration to say that without the aid of modern power implements a considerable number of the difficulties encountered could not have been surmounted.

Among the activities that have played important parts in bringing under the plough land that was formerly waste is soil drainage. There are still many thousands of acres that can be rendered productive if the water can be dispersed in a satisfactory way. To achieve this end, however, without mechanical means would be practically impossible, even in the absence of the present manuallabour shortage, and would assuredly take far longer than the conditions of the present contingency permit.

With this in mind, and creditable foresight, the Ministry of Agriculture and Fisheries plated, some time ago, an

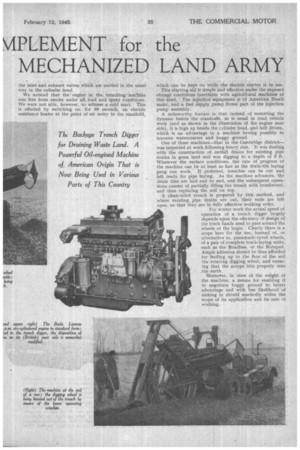

order for a number of Buckeye trench-digging machines. These appliances are built in the U.S.A., and the first batch, forming part of this order, has now arrived in Great Britain, and the machines have been assembled and prepared for work by J. Allen and Sons (Oxford), Ltd., Cowley, Oxford.

. Drivers have been trained for several of the Was Agricultural Executive Committees, a spares service has been established and the trench-diggers have been got into active commission. They are now working in various parts of the country—we have personally seen them in areas of the W.A.E.C.s for Oxford and Cambridge—and the number in use will steadily rise.

Power equipment for digging trenches. is not new, of course; the John Allen company, amongst others, has been

building machines of this nature for years, but the Buckeye outfit, which is one of several types and makes used by. the Ministry, has certain novel features.

Basis of the machine is a six-wheeled chassis with double drive. All wheels carry twin pneumatic tyres, and for conditions demanding it a track band can be fitted on each pair of driving wheels, At the rear of the chassis is a digging wheel driven by chain. The wheel revolves on rollers carried on a frame forming part of the boom, which is raised and lowered for travelling and digging positions, and for adjustments of digging depth. The buckets on the wheel scoop out the earth as the machine moves slowly forwards. At the top of the circle the earth is scooped out of the buckets on to a transverse conveyor belt, and then deposited on one or other side of the trench being dug, ready for the back-filling operation.

The trench width is 1 ft., and the depth can be adjusted up to 4 ft. Speed of cut, which, of course, depends upon the nature of the soil, and the driver's judgment, is from 2i ft, per minute upwards. A working speed commonly adopted is approximately 6 ft. per minute. In working order the machine weighs 7.1 tons. In addition to the conventional means for steering, there are two hand brakes, each of which operates on the rear wheels on only one side. These materially assist steering by retarding the wheels which are on the inside of the desired curve.

Whilst the front end of the chassis is sprung, the bogie is solidly connected to the frame. A notably wide range of gear ratios allows the machine to he driven, on the one hand, at usefully high road speeds when travelling from point to point, and on the other to crawl across fields, when digging, at the low speed quoted, namely, 0,028 m.p.h.

Power for traction, digging-wheel drive and conveyor-belt operation, is obtained from a .Buda-Lanova sixcylindered engine of 3t-in. bore and 5i-in. stroke. On this particular machine, when governed at 2,000 r.p.m. the maximum rating is 71.5 b.h.p., and 65.5 b.h.p. at 1,800 r.p.m. At 1,500 r.p:m the maximum torque is attained, namely, 220 lb.-ft.

As this engine is a standard unit intended for road-vehicle operation in the U.S.A.,, with its right-hand rule of the road, the majority of auxiliaries is grouped on what is in this country the off side of the unit.

A feature of the Buda engine' is the

Lanova combustion system, which has attained considerable popularity in America. A compression ratio of only 12 to 1 is used, and the injection pressure is 2,000 lb, per sq. in. A single-hole atomizer is horizontally placed, and injects. the fuel spray towards the venturi-form mouth of an air cell into which air is delivered ,under pressure by the action of compression; no fuel actnally enters the cell. During the expansion stroke, air rushing out of the cell is violently opposed to the fuel streare entering from the atomizer. Two swirl zones are provided in the combustion chamber proper forming, in plan, a figure of eight, located below

the inlet and exhaust valves which are carried in the usual way in the cylinder head, We noticed that the' engine in the trenching machine was free from smoke under all load and speed conditions. We were not able, however, to witness a cold start. This is effected by switching on, for 30 seconds, an electric resistance heater it the point of air entry to the manifold, which can be kept on while the electric starter is in use.

This starting aid is simple and effective under the exposed storage conditions inevitable with agricultural machines of this kind. The injection equipment is of American Bosch make, and a fuel supply pump forms part of the injection pump assembly.

A noteworthy feature is that instead of mounting the dynamo beside the crankcate, as is usual in road vehicle work (and as shown in the illustration of the engine near side), it is high up beside the cylinder head, and belt driven, which is an advantage in a machine having possibly to traverse watercourses and boggy ground.

One of these machines—that in the Cambridge district— was inspected at work following heavy rain. It was dealing with the construction of outfall drains for existing pipe drains in grass land and was digging to a depth of 3 ft. Whatever the surface conditions, the rate of progress of the machine can be at least as fast as the drain-tile laying gang can work. If preferred, trenches can be cut and left ready for pipe laying. As the machine advances, the drain tiles are laid end to end, and the subsequent operations consist of partially filling the trench with brushwood, and then replacing the soil on top. A clean-sided trench is prepared by this method, and where existing pipe drains are cut, their ends are left open, so that they are in fully effective working order.

For winter work the actual speed of operation of a trench digger largely depends upon the efficiency of design of the track bands used to pass around the wheels of the bogie. Clearly there is a scope here for the use, instead of, or alternative to, pneumatic-tyred wheels, of a pair of complete track-laying units, such as the Roadless, or the Rotaped. Ample adhesion should he thus afforded for feeding up to the face of the soil the rotating digging wheel, and ensuring that the scoops bite properly into the earth.

Moreover, in view of the weight of the machine, a means for enabling it to negotiate boggy ground to better advantage and with less likelihood 'of sinking in should markedly widen the scope of its application and its rate of working.