HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

553.—Improving the Lubricating System of the Dorman Engine on the Hallford.

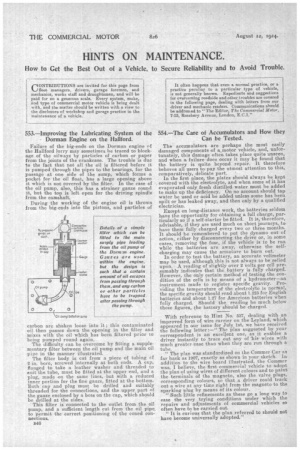

Failure of the big-ends on the Dorman engine ef the Hallford lorry may sometimes he traced to blockage of the oilways by particles of carbon or paper from the joints of the crankcase. The trouble is due to the fact that not all the oil is filtered before it is pumped through the pipes to the bearings, for the passage at one side of the sump, which forms a pocket for the oil float, has a large opening above it which is not covered by the filter. In the case of the oil pump, also, this has a strainer gauze round it, but the top is left open for the driving spindle from the camshaft.

During the working of the engine oil is thrown from the big-ends into the pistons, and particles of carbon are shaken loose into it ; this contaminated oil then passes down the opening in the filter and mixes with the oil which has been filtered prior to being pumped round again. The difficulty can be overcome by fitting a supplementary filter between the oil pump and the main oil pipe in the manner illustrated.

The filter body is cut from a piece of tubing of 2.in. bore, screwed internally at both ends. A cap, flanged to take a leather washer and threaded to cnit the tube, must be fitted at the upper end, and a plug, made on the same lines, but with a reduced inner portion for the fine gauze, fitted at the bottom. Both cap and plug must be drilled and suitably threaded for the connections, and the upper part nf the gauze enclosed by a boss on the cap, which should be drilled at the sides.

This filter is connected to the outlet from the oil pump, and a sufficient length cut from the oil pipe, to permit the correct positioning of the coned connections.

B46

554.—The Care of Accumulators and How they Can be Tested.

The accumulators are perhaps the most easily damaged components of a motor vehicle, and, unfortunately, this damage often takes place quite unseen, and when a failure does occur it may be found that the battery is quite beyond repair. It therefore behoves all users to. pay the utmost attention to this, comparatively, delicate part.

In the first place, the plates should always be.kept covered with the electrolyte and when some of it has evaporated only fresh distilled water must be added to make up the deficiency. On no account should tap water be used or acid be added unless some has been spilt or has leaked away, and then only by a qualified electrician.

Except on long-distance work, the batteries seldom have the opportunity for obtaining a full charge, particularly so if a self-starter be fitted. It is, -therefore, advisable, if they are used much on short journeys, to have them fully charged every two or three months. It should be remembered to put the. dynamo out of action, either by disconnecting the drive or, in some cases, removing the fuse, if the vehicle is to be run while the batteries are away, otherwise the selfcharging may cause the armature to burn out.

In order to test the battery, an accurate voltmeter may be used, although this is not always to be relied upon. A reading of slightly over 2 volts per cell presumably indicates that the battery is fully charged. However, the only certain method of testing the condition of the cells is by means of a hydrometer—an instrument made to register specific gravity. Providing the temperature of the electrolyte is normal, the specific gravity should read about 1.225 for English batteries and about 1.27 for American batteries when fully charged. Should the reading be much below these figures, the battery should be charged.

With reference to Hint No. 537, dealing with an improved form of wire carrier on the Leyland, which appeared in our issue for July 1st, we have received

the following letter The plan suggested by your correspondent is an excellent one, as it enables a driver instantly to trace out any of 'his wires with much greater ease than when they are run through a tube.

"The plan was standardized on the Commer Car as far back as 190'7, exactly as shown in your sketch. in addition to the wire board illustrated, the Commer was, I believe, the first commercial vehicle to adopt the plan of using wires of different colours and to paint the terminals of the magneto, also the valve plugs. corresponding colours, so that a driver could track out a wire at any time right from the magneto to the sparking plug by means of its colour. "Such little refinements as these go a long way to ease the very trying conditions under which the repairs and adjustments of commercial vehicles so often have to be carried out.

" It is curious that the plan referred to should not have become universally adopted."