A NEW MAGNETO FOR BUS SERVICE.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

An Interesting B.T.H. Model of the Polar-inductor Type.

AA.BSOLTJTE. dependability is one of :tithe most important qualities demanded from a unit intended for bug service, and this feature should be included iii its design, and conceived in Such a Way that, should it become necesSary to replace a part, this can he done

With ' facility and rapidity. These !Mints have been kept in mind by those l'esponSible•for the design of the latest magneto produced by the British Thomson-Houston Co., Ltd., Crown House, Aldwych, London, W.C.2, which, although somewhat of a novelty for bus work, is based upon the company's lengthy experience in the design and manufacture of magnetos for aircraft.

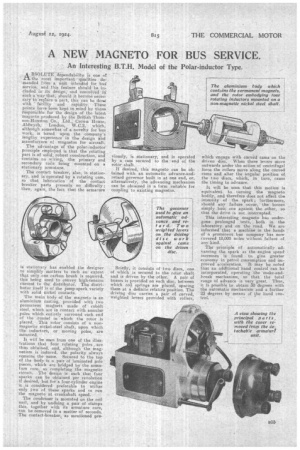

The advantage of the polar-inductor. principle employed is that the rotating part is of solid, robust construction, and contains no wiring, the primary and secondary coils being mounted on a stationary armature.

' The contact breaker, also, is stationary, and is operated by a rotating cam, so that lubrication of . the contact breaker parts presents no difficulty ; then, again, the fact that the armature

is stationary has enabled the designer to simplify matters to such an extent that only one carbon brush is required, this being used to convey high-tension current to the distributor. The distributor itself is of the lump-spark variety with solid nickel contacts.

The main body of the magneto is an aluminium casting. provided with two permanent magnets made of cobalt steel, which are in contact with annular poles which entirely surround each end of the tunnel in which the rotor is placed. This rotor consists of a nonmagnetic nickel-steel .shaft, upon which the inductors, or moving poles, are mounted.

It will be seen from one of the illustrations that four rotating poles are thus obtained, and, although the wagnetism is induced, the polarity always remains the same. Secured to the top of the body is a pair of laminated pole pieces, which are bridged by the armature core, so completing the magnetic circuit. The design is such that four sparks can be obtained per revolution if desired, but for a four-cylinder engine it is considered preferable to utilize only two of these sparks and to run the magneto at crankshaft speed.

The condenser is mounted on he coil. unit, and by undoing a pair of clamps this, together with its armature core, can be removed in a matter of seconds. The contact-breaker, as mentioned pre. viously, is stationary, and is operated by a cam secured to the end of the rotor shaft.

If desired, this magneto can be obtained with an automatic advance-andretard governor built in at one end, or, alternatively, the advancing mechanism can be obtained in a form suitable for coupling to existing magnetos.

Briefly, it consists of two discs, one of which is secured to the rotor shaft and is driven by the other. A pair of bosses is provided on each disc, between which coil springs are placed, spacing them at a definite relative position. The driving disc carries a pair of curved, weighted levers provided with rollers which engage with curved cams on the driven disc. When these levers move outwards under the action of centrifugal force the rollers move along the curved cams and alter the angular position of the two discs, which, in turn, cause the timing to advance.

It will be seen that this motion is equivalent, to turning the magneto bodily, and therefore does not affect the intensity of the spark; furthermore, • should any failure occur, the bosses simply butt one against the other, an that the drive is not interrupted.

This interesting magneto has undergone prolonged tests, both in the laboratory and on the road. We are informed that a machine in the hands of a prominent bus company has now covered. 18,000 miles without failure of any kind.

The principle of automatically advancing the spark as the engine speed increases is found to give greater economy in petrol consumption and improved acceleration. It may be noted that an ad&tional hand control can ha incorporated, operating the make-andbreak mechanism, so that the total range of advance is very great. Thus, it is possible to obtain 30 degrees with ttrholautomatie mechanism and a further' 23 degrees by means of the band con