A MOBILE CRANE FOR HEAVY FREIGHT.

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a New French Product which can Lift 31, tons at a Radius of 11 ft.

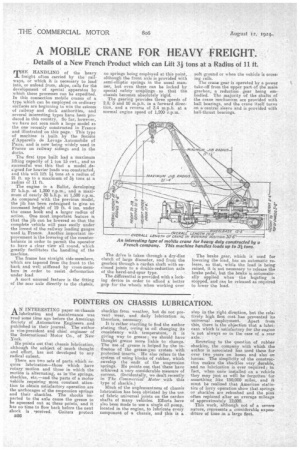

THE HANDLING of the heavy freight often carried by the railways, or which it is necessary to load into, or unload from, ships, calls for the development of special apparatus by which these processes can be expedited. In this connection mobile cranes of a type which can be employed on ordinary surfaces are beginning to win the esteem of railway and dock authorities, and several interesting types have been produced in this country. So far, however, we have not seen such a large model as the one recently constructed in France and illustrated on this page. This type of machine is built, by the Societe d'Appareils de Levage Automobile of Paris, arid is now being widely used in France on railway sidings and in the docks.

The first type built had a maximum lifting capacity of 1 ton 15 cwt., and so successful was this that a model designed for heavier loads was constructed, and this will lift 1 tons at a radius of 21. ft. up to a maximum of 3 tons at a radius of 11 ft.

The engine is a Ballot, developing 27 la.h.p. at 1,200 r.p.m., and a maximum of nearly 30 b.h.p. at 1,500 r.p.m. As compared with the previous model, the jib has been redesigned to give an increased height of 19 ft. 4 ins, under the crane hook and a larger radius of action. One most important feature is that the jib can be lowered so that the complete vehicle will pass easily under the lowest of the railway loading gauges used in France. Another important improvement is the lowering of the counter' balance in order to permit the operator to have a clear view all round, which greatly facilitates the handling of the machine.

The frame has straight side-members, which are tapered from the front to the back and well stiffened by cross-members in order to resist deformation under load A most unusual feature is the fitting of the rear axle directly to the chatsis, no springs being employed at this point, although the front axle is provided with semi-elliptic springs in the usual manner, but even these can be locked by special safety coupliegs so that the chassis becomes absolutely rigid.

The gearing provides three speeds of 2.8; 5 and 10 m.p.h. in a forward direction, and a reverse of 3.4 m.p.h. at a normal engine speed of 1,200 r.p.m.

The drive is taken through a dry-disc clutch of large diameter, and from the gearbox through a cardan shaft with enclosed joints to a double-reduetion axle of the bevel-and-spur type. The differential is provided with a locking device in order to afford a better grip for the wheels when working over soft ground or when the vehicle is crossing rails. The crane gear is operated by a power take-off from the upper part of the main gearbox, a reduction gear being embodied. The majority of the shafts of the crane mechanism are provided with ball bearings, and the crane itself turns on a central sleeve and is provided with ball-thrust bearings.

The brake gear, which is used for lowering the load, has an automatic release, so that, while the load is being raised, it is not necessary to release the brake pedal, but the brake is automatically, applied when the hsting is stopped, and can be released as required to lower the load.