Avoiding High Angles of Tip

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

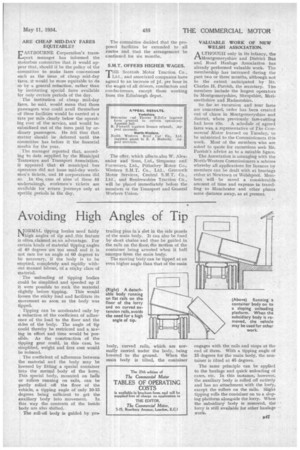

NORMAL tipping lorries need fairly high angles of tip and this feature is often,claimed as an advantage. For• certain kinds of material tipping angles of 40 degrees are too small and it is not rare for an angle of 60 degreeS to be necessary, if the body is to be emptied, completely and rapidly without manual labour, of a sticky class of material.

The unloading of tipping bodies could be simplified and speeded up if it were possible to rock the material slightly before tipping. This would loosen the sticky load and facilitate its movement so soon as the body was tipped.

Tipping can be accelerated only by a reduction of the coefficient of adherence of the load to the floor and the sides of the body. The angle of tip could thereby be restricted and a saving in effort and time would be possible. As the construction of the tipping gear could, in this case, be simplified, weight and first cost would be reduced.

The coefficient of adherence between the material and the body may be lowered by fitting a special container into the normal body of the lorry. This special body, mounted on balls or rollers running on tails, can be partly rolled off the floor of the vehicle, a tipping angle of only 10-15 degrees being sufficient to get the auxiliary body into movement. In this way the contents of the inside body are also shifted.

The roll-off body is guided by pro

trading pins in a slot in the side panels of the main body. It can also be fixed by short chains and thus be guided in the rails on the floor, the motion of the container being arrested when it half emerges from the main body.

The moving body can be tipped at an even higher angle than that of the main engages with the rails and stops at the end of them. With a tipping angle of 15 degrees for the main body, the container is tilted at 45 degrees.

The same principle can be applied to the haulage and quick unloading of cases, etc. In this instance, however, the auxiliary body is rolled off entirely and has no attachment with the lorry, except the rollers on the rails. Slight tipping rolls the container on to a sloping platform alongside the lorry. When the subsidiary body is removed, the lorry is still available for other haulage work.