• MAKING BEST USE OF THE FORD.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concern_Ling the Ford light chassis and ton truck, we endeavour to deal with the subject from every viewpoint, so that the advice will appeal to the owner, driver, maintenance engineer or mechanic.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any which are published.

326.—Stopping Engine Chatter.

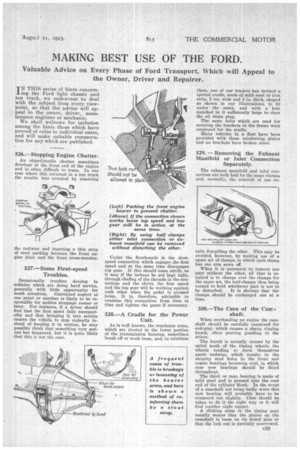

An objectionable chatter sometimes develops at the front end of the engine and is often difficult to trace. In one ease where this occurred in a ton truck the trouble was arrested by removing the radiator and inserting a thin strip of steel packing between the front engine joint and the front cross-member.

327.—Some First-speed Troubles.

Occasionally troubles develop in vehicles which are doing hard service, generally with little opportunity for much attention. Continued neglect at one point or another is likely to be responsible for sudden stoppage sooner or later. For instance, if a driver should find that the first speed fails unexpectedly and that bringing it into service causes the vehicle to stop violently instead of keeping it in motion, he may possibly think that something very serious has happened, but it is quite likely that this is not the case. Under the floorboards is the slowspeed connection which engages the first speed and at the, same time disengages top gear. If this should come adrift, as it may if the locknut be not kept tight, through chafing of the threads in the connection and the clevis, the first speed and the top gear will be working against each other when the pedal is pressed home. • It is, therefore, advisable to examine this connection from time to time and tighten the parts if necessary.

328.—A Cradle for the Power Unit.

As is well known, the crankcase arms, which are riveted to the lower portion of the transmission housing, sometimes break off or work loose, and, to reinforce these, one of our readers has devised a special cradle, made of mild steel or iron strip, 2 ins, wide and in. thick, shaped as shown in our illustrations, to fit under the sump, and with a hole punched in it sufficiently large to clear the oil drain plug.

The same bolts which are used for securing the brackets to the frame were employed for the cradle.

Many vehicles in a fleet have been provided with these reinforcing plates and no brackets have broken since.

329. — Removing the Exhaust Manifold or Inlet Connection Separately.

The exhaust manifold and inlet connection are both held by the same clamps and, normally, the removal of one en

tails disturbing the other. This may be avoided, however, by making use of a spare set of clamps, in which each clamp has one arm sawn off.

When it is necessary to remove one part without the other, all that is required is to change over the clamps for the spare set, the half-clamps then being turned to hold whichever part is not to

be disturbed. It is obvious that the clamps should be exchanged one at a time.

330.—The Care of the Cam shaft.

When overhauling an engine the camshaft should be carefully examined for end-play, which causes a sharp, ringing knock, ofteir proving puzzling to the driver.

The knock is actually caused by the spiral teeth of the timing wheels, the wheels tending to force themselves apart endwise, which results in the security stud holes in the front and centre bearings becoming oval, in which case new bearings should be fitted throughout.

The third, or rear, bearing is made of mild steel and is pressed into the rear end of the cylinder block. In the event of a camshaft not being badly worn this new bearing will probably have to be rearnered out slightly. Care should be taken to fit it the right way or it will foul number eight tappet.

A clicking noise in the timing gear usually means that the pinion an the camshaft is loose on its dowel pins or that the lock nut is partially unscrewed.