Savage.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Savage Brothers, Limited, St. Nicholas Iron Works, King's Lynn (Stand No. 189, Minor Hall).—The 6ton wagon exhibited by this company is a very good example of type A. The whole vehicle presents a business-like appearance, and gives one the impression that large wearing surfaces, together with accessibility, have been the keynotes in carrying out the design, whilst the well-proportioned parts imply great strength.

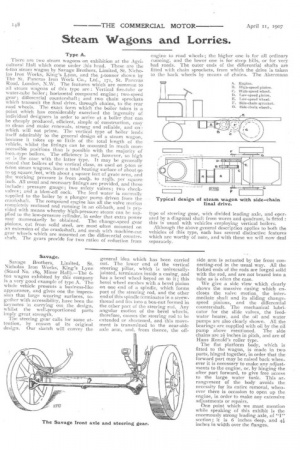

The steering guar calls for some attention, by reason of its original design. Our sketch will convey the

general idea which has been carried out. The lower end of the vertical steering pillar, which is universallyjointed, terminatesinside a casing, and has a bevel wheel keyed on to it ; this bevel wheel meshes with a bevel pinion on one end of a spindle, which forms part. of the steering rod, and the other end of this spindle terminates in a screwthread and fits into a box-nut formed in the other part of the steering rod. Any angular motion of the bevel wheels, therefore, causes the steering rod to be extended or shortened, and this movement is transmitted to the near-side axle arm, and, from thence, the off

side arm is actuated by the front connecting-rod in the usual way, All the forked ends of the rods are forged solid with the rod, and are not brazed into a tube as is often the case.

We give a side view which clearly shows the massive casing which encloses the valve motion, the intermediate shaft and its sliding changespeed pinions, and the differential countershaft. The mechanical lubricator for the slide valves, the feedwater heater, and the oil and water pumps are also clearly shown. All the bearings are supplied with oil by the oil pump above mentioned. The side chains are 2+ inches in pitch, and are of Hans Renold's roller type.

The flat platform body, which is fitted to the wagon, is made in two parts, hinged together, in order that the forward part may be raised back whenever it is necessary to make any adjustments to the engine, or, by hinging the after part forward, to give free access to the large water tank. This arrangement of the body avoids the necessity for its entire removal, whenever there is occasion to open up the engine, in order to make any extensive adjustments or repairs.

One point which we must mention while speaking of this exhibit is the enormously strong leading axle, of "I" section ; it is 6 inches deep, and 4A inches in width over the flanges.