• When Crane Fruehauf's Tony Palmer talks about moves to

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

increase permitted trailer lengths as "the next great battle", he says it with a mixture of resignation and relish. He is dearly sanguine about confronting the obstacles that often beset the industry; yet he also seems to draw pleasure from arguing his case. "Whatever the problems that affect dry-freight trailers, with reefers they are magnified. All we can do is present a logical case in the best way we know, and hope that the decision-makers see the sense of it."

Palmer is probably more qualified than most people to pronounce on the refrigerated transport scene. Besides heading the market research team at Crane Fruehauf, Britain's biggest trailer builder, he is also a director of Transfrigoroute (UK) which is Britain's affiliate to the International Transfrigoroute-operators' and manufacturers, organisation. Much of his time is spent weighing-up market needs, putting them in the context of existing and anticipated legislation, and pressing for change when needed.

The question of trailer-length limits is very much a live issue. Operators want to be able to carry 26 metric pallets of the popular 1,200mm x 1,060mm size, and Palmer sees the answer in an overall length-limit increase for articulated outfits from 15.5 to 16.5 metres. "There are other ways of achieving 26 pallets," he admits, "but the 16.5-metre length-limit looks like the solution that is going to be most acceptable overall."

One way to achieve it is to use a very long trailer and a tractive unit with a very short cab — often with a roof-top sleeper compartment. This is already legal in Britain, and elsewhere in the Common Market, but in some respects is unsatisfactory. "For a start," says Palmer, "you need to use an undermount refrigeration unit to keep the trailer front overhang down. These are more costly and complicated than front-mounted units, and they take up space that operators like to use for spare pallets." Perhaps more to the point, he says, these very long trailers can be used only with the special short tractive units — a constraint that can cause operational problems, and leads to overlength running if a standard unit has to be substituted because of breakdown. Also, driver pressur€ against cab-roof sleepers is mounting: "They're claustrophobic, and they exaggerate pitching," they say.

The best solution, in Palmer's view, is the EEC's proposed overall length increase to 16.5 metres. Indications are that this will be adopted soon, and France is already threatening to jump the gun by introducing it unilaterally in January. As it

Lands now, the proposal will be accompaied by a maximum kingpin to rear-end imension of 12 metres and an effective .ailer-length limit (governed by swing learance) of 13.7 metres.

"In practice, you still need an underbunt refrigeration unit in order to fit in 6 pallets," says Palmer. "If you use a .ont-mounted unit, the need for adequate wing clearance cuts down effective deckaigth to 3.4 metres, but at least you get -ue interchangeability between standard .actor units."

In any case, as Palmer points out, nother metric pallet size is quickly ping in popularity. This is the 1,200mm x DOrnm size, and at 16.5 metres it is ossible to fit the industry's target of 32 f these into a refrigerated body and still se a front-mounted refrigeration unit. "I ink we'll be seeing a lot more of these nailer pallets in future," he predicts.

If overall length is Palmer's next great attle, his last was width, but this he sees well and truly won. The UK limit for !mperature-controlled traffic goes up ext January from 2.58 to 2.6 metres. almer is somewhat nettled, though, that se operators' associations have claimed redit for winning this increase: "It was ransrigoroute in general and Crane ruehauf in particular that led the camaign, not the FTA or the RHA. We rorked on it for two years," he says.

:ONCESSIONS

almer reacts swiftly to any suggestion bat operators will forever press for more mensional concessions. "The whole Dint about the 2.6-metre limit is that it efines a minimum sidewall thickness of 5mtn. That effectively rules out any clevr tricks with thin walls. On the other and it's ideally suited to existing metric allets. The transport industry would have invent a new pallet size worldwide be re another width increase was needed, id I don't think that's likely to happen in ie near future."

There is a slight anomaly in that the idth increase applies only to imperature-controlled traffic, whereas le proposed length limit will apply across ie board. "The two cases are quite diffeent, though," asserts Palmer. "Wider ry-freight bodywork just doesn't make ense, given that existing dry-freight metc pallets can be carried quite happily at .5 metres. On the other hand, a length crease will benefit both types of traffic.

fact there's no case that I can see for ifferential length limits.

One thing these changes have done is liminate the appeal of thin-walled reigerated vehicles virtually at a stroke. "I an't see them having any further attracon, except perhaps for chill-temperature cirk. Then they might be cheaper, espe ally if they didn't need ATP testing". The ATP (Accord Transports Perissables) agreement remains a political minefield, says Palmer: "International authorities are still struggling towards universal recognition of test certificates, so that equipment need not be tested in the country of origin."

One step forward has been an acceptance in Britain of separate testing of bodywork and refrigeration plant. The manufacturing industry had complained that British insistence on testing the fridge plant in situ was yielding less favourable results than separate testing abroad.

Growth in the popularity of multicompartment refrigerated bodywork has now blown up a new cloud on the ATP horizon. There is no standard method of testing these bodies, especially where a moveable bulkhead is concerned. "Some authorities test the whole body, others just the refrigerated part," says Palmer.

He is, however, slightly sceptical about the current vogue for multi-compartment bodies. "Reports indicate that it's extremely difficult to maintain a wide range of temperatures reliably in a single body," he says, although he acknowledges that they can be ideal for some specialised applications; "but I suspect that the larger market growth is manufacturer-led. Personally I can't see it continuing — not when the trend among operators is towards more and more single-drop out-of town warehouse complexes."

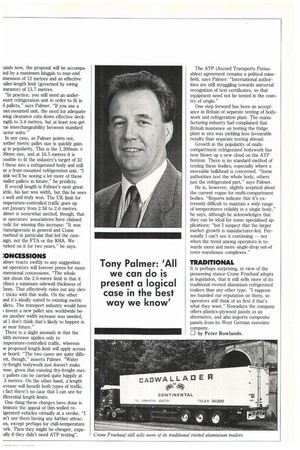

TRADITIONAL

It is perhaps surprising, in view of the pioneering stance Crane Fruehauf adopts in legislation, that it still sells more of its traditional riveted aluminium refrigerated trailers than any other type. "I suppose we founded our reputation on them, so operators still think of us first if that's what they want." Nowadays the company offers plastics-plywood panels as an alternative, and also imports composite panels from its West German associate company. O by Peter Rowlands.