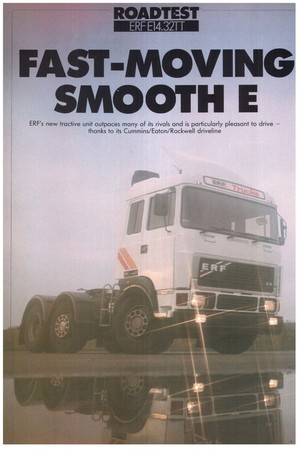

FAST MOVIN SMOOTH E

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

ERF's new tractive unit outpaces many of its rivals and is particularly pleasant to drive thanks to its Cummins/Eaton/Rockwell driveline

I As it replaces the C Series tractive ERF's latest range might logically .ve been called D Series. Not surprisgly, that idea was dismissed at an early age. The last thing Peter Foden and s team at Sandbach wanted was their A.NT trucks to be associated with an old nge of Ford middleweights with a longice-superseded cab, even though it as a bestseller in its time.

One of ERF's prime objectives in deloping what is now called the E Series as to bring its own SMC (sheet oulding compound) plastic panelled cab to date to enhance its driver-appeal. three-day test of one of the latest REs has allowed us to assess just how ell that has been done.

The new model designation is based engine capacity and power rating. ence the E14.32 TI' which we tested id a 14-litre Cummins engine with a 19kW (320hp) gross maximum power ting, which becomes 224kW (301hp) to the EEC 80/1269 standard. The Ti' suffix denotes tandem-steer active unit. A 6 x 4 E Series with the Inc engine would be designated E14.32

ERF adopted Cummins engines, Eaton arboxes and Rockwell axles as its tandard" driveline about two years ago. t the time that decision was considered introversial. Now, at Sandbach at least, is deemed to have been a success — it intinues with the E Series. However, . a comparison of this vehicle's specificam with that of the CP Series 6 x 2 hich we tested in October last year :M October 26, 1985) shows there are g differences between the old and new ivelines. The 12-speed Twin Splitter SO 11612 has replaced the nin-speed TX 11609 as the standard gearbox bend engines of 216kW (290hp) and )ove, and the new Rockwell CVC S i0E axle from Cameri, Italy has reaced the Alcester-built R 180E. This Ives a few kilos in unladen weight and .duces design gross weight from 1,0()Okg to 38,(00kg in the process. • PERFORMANCE

Compared with the LTA 10-290 powered CP Series 6 x 2, this E Series with a virtually identical chassis and broadly similar overall gearing gives considerably faster journey times, but uses fuel at a much less economical rate. It also demands a different, more disciplined driving style which keeps engine speed down in the 1,200-1.700 rpm band if fuel economy is not to suffer further.

Nonetheless, as the histograms on page b1 how, compared with three major 6 x 2 rivals from Daf. Iveco and Mercedes with similarly rated engines, the NTE 320 powered E Series fuel economy is by no means bad. We have not compared overall fuel economy and with this ERE our route through Scotland has changed slightly, now by-passing Perth.

The test results show clearly how the E 14.32 outpaces its rivals at 38 tonnes over many kinds of road and gradient. Yet again much of the credit for this must go to Eaton's Twin Splitter gearbox, which permits gearchanges so fast that it can have a marked effect on journey times, particularly over severe gradients.

More impressive from the driver's viewpoint, very few whole-lever movements are needed with the Twin Splitter. Also, the clutch pedal does not have to be used except when moving off from rest and when very fast changes up are required.

On level ground the fully-laden E 14.32 will move off from rest without complaint in fourth gear, that is with the gear lever pulled back into what would be second gear position in a conventional H gate, four-ratio box, and with the three-position splitter button in low.

To accelerate from rest up to 96km/h requires only two more whole-lever movements. The rest of the 4, 6, 8, 9, 10, 11, 12 sequence is effected simply by using the splitter button. Provided the changes are timed reasonably well and the accelerator pedal controlled finely, the clutch pedal can be ignored for all gearchangcs, up and down.

The big Cummins engine with its PT fuel injection system takes noticeably longer to slow down when the accelerator pedal is released than other engines with conventional in-fine pumps, like the Perkins Eagle for example. This makes Twin Splitter changes up through the ratios without the clutch slightly slower on this truck than on others we have driven. On downhill or flat sections this simply means that a little patience is required. On steep climbs Eaton's latest multi-plate inertia brake, or "upshift brake" as the Americans call it, becomes a boon.

An air switch at the bottom of the clutch pedal's travel activates the brake, which on the latest Twin Splitter boxes is housed inside the main casing out of sight. No matter how long the clutch pedal is held fully depressed the brake will operate only for about half a second in slowing down and synchronising the gear's output and input shafts, so the change should be made as soon as thiclutch pedal is depressed.

At one point during our test when the brake was being worked particularly hard it began to emit an odd screech, but apart from surprising the ERF engineer and us, this seemed to have no harmful effects and certainly did not detract from the device's effectiveness.

• CAB COMFORT Largely by paying careful attention to detail ERF has greatly uprated its old SP3 cab's standard of driver appeal with the latest SP4 model. The basic cab structure of a steel frame panelled with SMC plastic panels is unmistakeably unchanged, which will be regarded as no bad thing by ERF operators who have already come to appreciate the cab's eight-year warranty against corrosion. From the driver's seat, however, everything looks very different. Gone is the flat, steeply-angled instrument and switch panel (which we considered fussy and old-fashioned) to be replaced by a much more up-to-datelooking facia.

All of the gauges, which are shaped like an inverted D, are housed behind a single piece of non-reflective, toughened glass, Leyland 145 style. They are generally easy to read at a glance, even at night thanks to some excellent back lighting. Only the three on the extreme offside edge of the panel present any difficulty. We found that these — the battery charge, fuel level and, to a lesser extent, engine temperature gauge — were obscured by the rim of the steering wheel.

The tachograph on our test vehicle, mounted to the left of the instrument panel, was Lucas Kienzle's latest electronic model, which, in keeping with the rest of the truck, is much smoother in operation than the model it supersedes. There is now no sign of the irritating jerky needle movement which used to make it difficult to hold a steady speed.

The new position for the park brake lever, on the section of the dashboard which is linked back towards the driver, will take a little getting used to for those who have been accustomed to earlier ERFs, but its action, too, is smooth and finely graduated, making hill restarts easy to control.

It is clear from some of the minor modifications to the SP4 cab that ERF's engineers have taken careful note of driver requirements and of criticisms of the earlier cab. The rocker switches are clearly marked and not too small, as is the new rotary light switch. The exhaust brake control button has been moved to a sensible position just behind the base of the steering column where it can easily he reached; the heater controls are now illuminated; and there is an abundance of really useful stowage space, including spring loaded cassette storage racks in the console mounted on top of the engine cover.

ERF's distinctive, Thomas Electronics bleeper warning for the indicators has been retained on the latest models, which we welcome.

The new, rectangular, Hella headlamps certainly have a more useful dipped beam than the old circular lens type, but the plastic panels on which they are mounted still vibrate alarmingly, causing the beams to quiver and surely effect lamp filament life.

Very wet weather during the first two days of the test gave us the chance to test to the full ERF's claims for its new front corner pillar air deflectors which an supposed to help keep the minors and side windows clear of road dirt. They do, although we suspect that the step rings which cover the wheel nuts on the front axle (and which are not new) must also help at least a little.

• RIDE AND HANDLING ERF's wholly new four-point cab suspension system, with Aeon hollow rubber springs and dampers at the front and coil springs and dampers at the rear, is high13 effective in isolating the driver from man:

• the high-frequency vibrations he could cpect to feel through the old, essentially zid, front cab mounts. A brief drive in an 'laden 4 x 2E—Series at Sandbach had invinced us of that before this test arted. On a 6 x 2 tractive unit coupled a mechanically sprung semi-trailer such ; ours, with its bogie mounted at the ctreme rear, the cab suspension is not ilk so obviously effective. This is simply !cause it is having to cope with a lot ore lower-frequency flexing of the ailer chassis. However, we believe that ith most semi-trailers few drivers will id any reason to criticise any aspect of E !ries ride and handling. • BRAKING The 6 x 2 we tested last October had Lucas Girling fixed cam sliding shoe foundation brakes; this E Series had GKN Kirkstall S-cam components, but we could detect no difference in performance between the two types. Indeed, the rolling road braking efficiencies we measured were virtually identical. ERF's policy now is to use Lucas Girling brakes on rigids and Kirkstall components on tractive units.

The Retro exhaust brake on this E Series was as effective as we have come to expect from this type, the 14 litres of the NTE 320 engine helping retardation more than smaller capacity engines would. • SUMMARY ERF's resources for research and development are only a fraction of those available to many of its competitors. Yet it continues to produce tractive units which more than hold their own against rivals.

By paying careful attention to detail the company has brought its distinctive cab right up to date and enhanced its driver appeal.

A Cummins, Eaton, Rockwell driveline seldom fails to give good results over CM's test route, particularly when the middle bit is a Twin Splitter. 0 by Tim Blakemore