ECONOMICAL MEDIUM-LOAD CHASSIS.

Page 109

If you've noticed an error in this article please click here to report it so we can fix it.

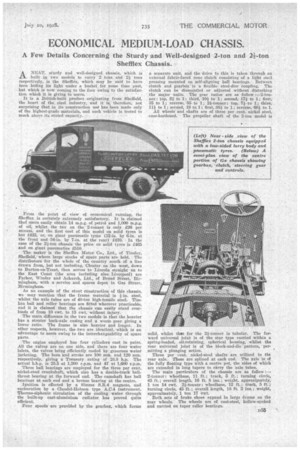

A Few Details Concerning the Sturdy and Well-designed 2-ton and 2i-ton Sheffiex Chassis.

ANEA9_', sturdy and well-designed chassis, which is built in two mOdels to carry • 2 tons and 24 tons respectively, is the Shelf:lex, which may be said to have been hiding its light under a bushel for some time past, but which is now .coming to the fore owing to the satisfaction which it is giving to users.

• It is a British-built product originating from Sheffield, the heart of the steel industry, and it is, therefore,. not surprising that in its construction us has been made only of the highest-grade materials, and each vehicle is tested to much above its stated capacity.

From the point of view of economical running, the Shefflex. is certainly extremely satisfactory. It is claimed thai users easily obtain 14 m.p.g. of petrol and 1,000 m.p.g. of oil, whilst the tax on the 2-tonner is only £26 per annum, and the first Cost of this model on solid tyres is but 4425, or, on giant pneumatic tyres (32-in. by 6-in, at the front and 34-in. by 7-in at the rear) £470. In the case of the 21-ton chassis the price on solid tyres is £465 and on giant pneumatics £510.

The maker is the Shefllex Motor Co., Ltd., of Tinsley, Sheffield, where large stocks of spare parts are held. The distributors for the whole of the country south of a line drawn from, but not including, Chester on the west, down to Burton-on-Trent, then across to Lincoln straight on to the East • Coast (the area including also Liverpotil) are Parker, Winder and Achurch, Ltd., of Broad Street, Birmingham, with a service and spares depot in Gas Street, Birmingham.

As an example of the stout construction of this chassis, we may mention that the frame material is 4-in, steel, whilst the axle tubes are of 40-ton high-tensile steel. Timken ball and roller bearings are fitted wherever practicable, and it is claimed that the chassis can easily stand overloads of from 10 cwt. to 15 cwt. without injury.

The main difference in the two models is that the heavier has a stouter back-axle easing and a worm gear giving a lower ratio. The frame is also heavier and longer. In other respects, however, the two are identical, whic is an advantage to users owing to the interchangeability of spare parts.

The engine employed has four cylinders cast in pairs. All the valves are on one side, and there are four water inlets, the valves being efficiently cooled by generous water indicting. The bore and stroke are 100 mm. and 120 mm. respectively, giving a Treasury rating of 24.8 h.p. The actual b.h.p. is 25.5 at 1,200 r.p.m. and 47 at 1,600 r.p.tn.

Three ball bearings are employed for the three per cent. nickel-steel crankshaft, which also has a double-track ballthrust bearing at the forward end. The camshaft has hall bearings at each end and a bronze bearing at the centre.

Ignition is effected by a Simms S.R.4 magneto, and carburation by a CIaudel-lfobson type A.C,4 instrument. Thermo-siphonic circulation of the cooling water through the built-up cast-aluminium radiator, has proved quite

efficient. .

Four speeds are provided by the gearbox, which forms

a separate unit, and the drive to this is 'taken through an external fabric-faced cone clutch consisting of a light steel pressing mounted on .self-aligning ball bearings. Between clutch and gearbox' is a flexible steel-disc coupling. The clutch can be dismantled or adjusted without disturbing the major units. The gear ratios are at -follow ;2-tonnor : top, eg to 1; third, 10i to 1; second, 174 to 1; first, 35 to 1; reverse, 55 to 1; 24-tanner t top,. 74 to 1 ; thirff, 114 to 1; second, 10 to 1; first, 381 to 1; reverse, 604 to L All wheels and shafts are of three per .cent, nickel steel, case-hardened. The propeller shaft of the • 2-ton model is

solid, whilst that for the 24-tonner is tubular. The forward universal joint is of the star type carried within a spring-loaded, oil-retaining, spherical housing, whilst the rear Universal joint is of the block-and-die pattern, permiffing a plunging action.

Three per cent, nickel-steel shafts are utilized in tht rear axle. These are splined at each end. The axle is of the fully floating type with a centre pot, the sides of which are extended in long tapers to carry the axle tubes.

The main particulars of the chassis are as follow :— 2-tanner: wheelbase, 11 ft.; track, 5 ft.; turning circle, 45 ft.; overall length, 16 ft. S ins. ; weight, approximately, 1 ton 14 cwt. 24-tonner : wheelbase, 12 ft.; track, 5 ft.; turning circle, 45 ft.; overall length, 18 ft. 2 ins.; weight, approximately, 1 ton 1.7 cwt.

Both sets of brake shoes expand in large drums on the rear wheels. The wheels are of cast-steel, hollow-spoked and carried on taper roller bearings.